Conveyor systems help “convey,” or move, packages, food, products or equipment from area within a facility to another, usually for simple transportation or to perform the various stages of automated or semi-automated manufacturing or finishing. Read More…

VAC-U-MAX is a premier manufacturer of quality conveyors among other similar products and services. VAC-U-MAX produces its equipment to handle small parts and heavy metal powders.

mk North America, Inc. offers the widest variety of conveyors in the industry. Our vast product line features a variety of aluminum frame and stainless-steel conveyors that are built to last. At mk we believe in offering not only a better product, but also a better solution – which is why we will work with you to ensure your unique application is matched with the best possible conveyor...

At Slate River Systems Inc, we take pride in our expertise as innovators in the field of conveyor systems. With years of collective experience, our team is committed to delivering cutting-edge solutions tailored to meet the diverse needs of our clients. Our conveyor systems are engineered to optimize efficiency and streamline material handling processes across various industries.

Redline Systems, Inc. is a leading provider of innovative conveyor solutions. They offer various conveyor types, including portable belt conveyors, incline conveyors, horizontal conveyors, stainless conveyors, and more. Experience the difference with Redline Systems, where innovation meets reliability in conveyor technology.

Impact Automation stands as a prominent force in the field of automation, specializing in the design and implementation of advanced conveying systems tailored for diverse manufacturing processes. With a focus on efficiency, precision, and adaptability, we offer a comprehensive product range that includes sorter feed systems, sorter solutions, traditional conveyors, and plastic belt conveyors.

Spiroflow offers a complete range of mechanical conveying solutions in the industry. The staff at Spiroflow can recommend the best method to meet your conveying needs.

Vecoplan leads the charge with cutting-edge technologies that revolutionize waste and recycling. From versatile shredders and granulators to efficient conveying and sorting systems, Vecoplan offers a wide array of solutions for handling wood, paper, plastics, textiles, and more. Our tailored equipment sets new industry standards, meeting the demands of even the most challenging applications.

More Conveyor Manufacturers

Conveyor System Applications

Conveyor systems serve myriad purposes across diverse industries, significantly optimizing operations by facilitating the movement of materials and products. In manufacturing, they play a pivotal role in automating production lines by efficiently transferring raw materials, components, and finished goods between various stages of the manufacturing process. This integration ensures a continuous workflow, boosting productivity while minimizing errors and delays associated with manual handling.

In logistics and distribution, conveyor systems are indispensable in warehouses and distribution centers, where they streamline the transportation of packages, parcels, and pallets. This capability enhances order fulfillment efficiency and optimizes inventory management by swiftly and accurately handling high volumes of goods. As a result, conveyor systems contribute to expedited order processing and heightened customer satisfaction.

Conveyor systems play a crucial role in airport operations, particularly for handling baggage. They seamlessly shuttle luggage between terminals, check-in counters, security points, and aircraft, streamlining operations. Automating this process reduces the risk of lost baggage, boosts efficiency, and enhances the overall passenger journey.

In mining and quarrying, conveyor systems are indispensable for transporting bulk materials like ores, coal, and aggregates. These systems efficiently move materials over extensive distances, cutting down on manual labor and ramping up productivity. They also prioritize safety by minimizing worker exposure to hazardous environments.

Conveyor systems present a versatile solution across various industries, enhancing operational efficiency, cutting costs, and boosting productivity. Whether deployed in manufacturing, logistics, airports, or mining, these systems streamline material handling, reduce reliance on manual labor, and ensure seamless goods flow between points.

History of Conveyor Systems

In approximately 1795, the initial conveyor system emerged as a belt conveyor composed of leather belts moving over wooden surfaces. Operated by hand cranks and pulleys, these systems primarily served shipyards, facilitating the transfer of agricultural products onto ships.

The integration of steam technology, already existing at the time, marked a significant advancement. By 1804, the British Navy employed the first steam-powered conveyor belt, employing it in ship kitchens to produce biscuits for sailors.

During the Industrial Revolution, conveyor systems saw significant advancements. In 1892, Thomas Robins made pivotal inventions that revolutionized material handling in mining, culminating in the creation of the first conveyor belt for transporting ores and coal. Following this milestone, in 1901, the Swedish company Sandvik introduced the inaugural steel belt conveyor, designed specifically for bulk mining materials such as charcoal and gravel. Soon after, in 1905, Irish engineer Richard Sutcliffe pioneered the first underground conveyor belt, marking another leap forward in coal transportation efficiency. Henry L. Jennings, an American citizen, further refined conveyor technology in 1908 with his roller conveyor patent, featuring internal ball bearings that greatly enhanced the smooth transmission of goods. These innovations collectively streamlined coal transport, drastically reducing both time and labor.

In 1913, Henry Ford revolutionized the early conveyor market by introducing assembly lines with conveyor belts at his Highland Park, Michigan factory. This innovation drastically accelerated the production of Model T cars, setting a new standard in efficiency. By 1919, conveyor belt assembly became ubiquitous in the automotive industry, following Ford’s pioneering example.

During World War II, the demand for materials spurred the development of numerous synthetic alternatives. This era saw the emergence of key conveyor belt materials like urethane and synthetic rubber, providing manufacturers with advanced options for assembling their conveyor systems.

In 1957, B.F. Goodrich introduced a breakthrough in conveyor systems by patenting a belt with a half-twist, distributing wear evenly across its surface rather than concentrating it in one area. However, advancements in material technology have rendered this design obsolete as modern materials now boast sufficient durability without needing such innovations.

The modern era of conveyor systems is often dated to around 1970, marked by a Louisiana-based company’s pioneering patent for a belt constructed entirely from modular plastic components. Today, conveyor systems have evolved significantly, offering greater diversity, efficiency, and durability than ever before. They have proven so reliable that they can span impressive distances. For instance, the world’s longest conveyor stretches across the Western Sahara, covering over 60 miles to transport phosphate from a mine to the coast.

How Conveyor Systems Work

Conveyor systems function by using belts, chains, or rollers to transport items from one place to another. These systems are built with several essential components. A conveyor belt, made from tough materials like rubber or metal, loops around a series of pulleys or rollers, forming an endless moving surface. An electric motor-powered drive unit supplies the energy needed to move the belt. Depending on the design, the drive unit can be situated at one end of the conveyor or spread out along its length. Tensioning devices keep the belt tight and correctly aligned.

When the motor activates the drive unit, the conveyor belt begins its motion, transporting items along its path. Sometimes, the belt itself acts as the carrying surface, while in other scenarios, additional attachments such as trays, buckets, or pallets are utilized to hold the items. The conveyor’s speed and direction can be adjusted, enabling accurate handling and positioning of goods.

Conveyor systems can be enhanced with various additional components to improve their performance. These may include rollers or wheels for smoother operation, sensors for automated item sorting and diversion, and controls for adjusting speed, starting, and stopping.

Conveyor systems offer a dependable and efficient way to move goods within a facility. Their adaptability to various applications, sizes, and load capacities makes them versatile solutions across numerous industries.

Types of Conveyor Systems

Conveyor systems can employ a variety of types to move parts or products throughout a facility, onto the next finishing stage, or along the assembly line. Among these, belt conveyors are the most frequently used, followed by chain, roller, spiral, overhead, and vertical conveyors. Additional types include food, industrial, gravity, pneumatic, and screw conveyors.

Belt Conveyor

The conveyor belt system features a broad belt, typically crafted from rubber or another type of polymer, that loops around unidirectional rollers. These systems comprise multiple conveyor belts, facilitating linear motion for the belts and the items they transport.

Pallet Conveyor

Belt conveyors excel at transporting heavy industrial items such as pallets and grid boxes, outperforming other conveyor systems. When belt conveyors are specifically designed to carry pallets, they are known as “pallet conveyors.”

Timing Belt Conveyor

Timing belt conveyors are designed to move items with precise synchronization and positioning. They utilize toothed belts that engage with matching pulleys, ensuring accurate and controlled movement. This makes them ideal for applications requiring exact spacing, such as assembly lines, indexing operations, and the transportation of products in specific sequences.

Chain Conveyor

Chain conveyors operate on a similar principle to belt conveyors but utilize chains instead of rollers. These chains, often multiple and parallel, are looped around a series of wheels. This design is primarily used to transport unfinished metal parts through washing processes and to carry powdered metal parts through ovens for drying or sintering.

Both belt and chain conveyors are integral to the majority of conveyance needs in various industries, including parts manufacturing, food processing and packaging, as well as general consumer and commercial product manufacturing.

Roller Conveyor

Another common type of conveyor is the roller conveyor. This system moves items using individual rollers aligned parallel to each other. For optimal performance, the conveyor needs to be set up on a flat surface with ample space. Roller conveyors are typically used to transport equipment and food within a facility or guide items through various stages of automated manufacturing and finishing.

Spiral Conveyor

The term “spiral conveyor” can refer to two distinct conveyor designs, both of which integrate seamlessly with standard conveyors. The first design features belts or slats to elevate food products, parcels, packages, boxes, and other individual items vertically. This type of spiral conveyor is tailored for parts assembly warehouses, shipping warehouses, food and beverage manufacturers, airports, and other industrial settings that need to vertically move delicate or large packages. The second design utilizes an enclosed screw mechanism to lift loose bulk particles vertically.

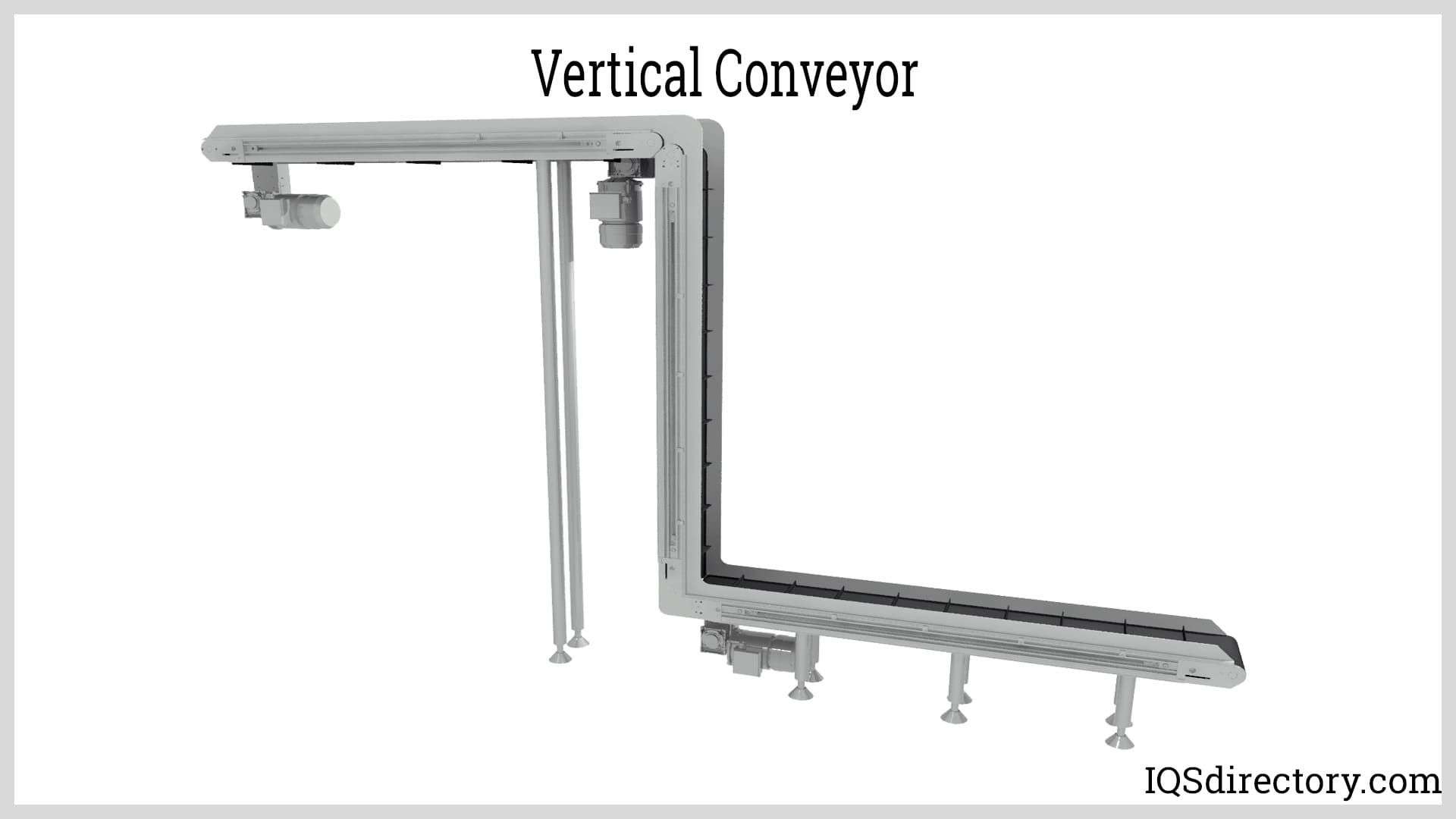

Overhead Conveyor

Overhead conveyor systems carry items throughout a facility, moving them through various processing stages such as spray painting, drying, or baking. Vertical conveyors, on the other hand, elevate items between levels using magnets, platforms, or grippers attached to moving chains or belts. Although they are not frequently seen, they are typically employed to transfer food items or mechanical parts when in use.

Food Conveyor

Food conveyors, as the name implies, are specifically designed for transporting food. These conveyors, made predominantly of stainless steel due to its FDA-approved sanitary properties, handle both raw and cooked food. To prevent cross-contamination, they are regularly cleaned with power washers. Common features include weight scales, metal detectors for quality inspection, and robotic arms for sorting. Food conveyors are typically integrated into larger systems that include sorting systems, wrapping and labeling machines, case packing systems, freezers, and cool rooms. While mostly automated, employees often work alongside them to ensure proper management and quality control of the food.

Industrial Conveyor

The term “industrial conveyor” encompasses conveyors and conveyor systems employed by manufacturing companies. These systems facilitate the movement of materials and products within a designated warehouse or factory area.

Gravity Conveyor

Conveyors typically operate with motorized mechanisms, yet certain types, like ball transfer and chute conveyors, rely on gravity. These gravity conveyors utilize the natural pull of gravity to propel items along an inclined path, eliminating the need for electrical or mechanical power. The primary categories of gravity conveyors are gravity roller conveyors and gravity wheel conveyors.

Gravity Roller Conveyor

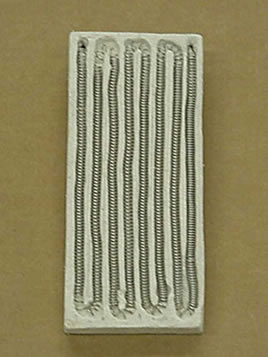

Gravity roller conveyors transport products horizontally across a pathway lined with a series of rollers. These rollers, positioned perpendicular to the direction of travel, are supported by shafts on bearings to ensure smooth movement. The shafts are secured within structural or formed frames using internal springs or retaining pins. Since the system relies on gravity, products can either be manually pushed along the horizontal path or move downward on a slight incline.

Gravity Wheel Conveyor

Gravity wheel conveyors, often referred to as gravity skatewheel conveyors, utilize a pathway of wheels instead of rollers. These conveyors are lighter in weight compared to gravity roller conveyors. They are designed for handling lighter loads and reducing accumulation, especially when operating at minimal decline angles.

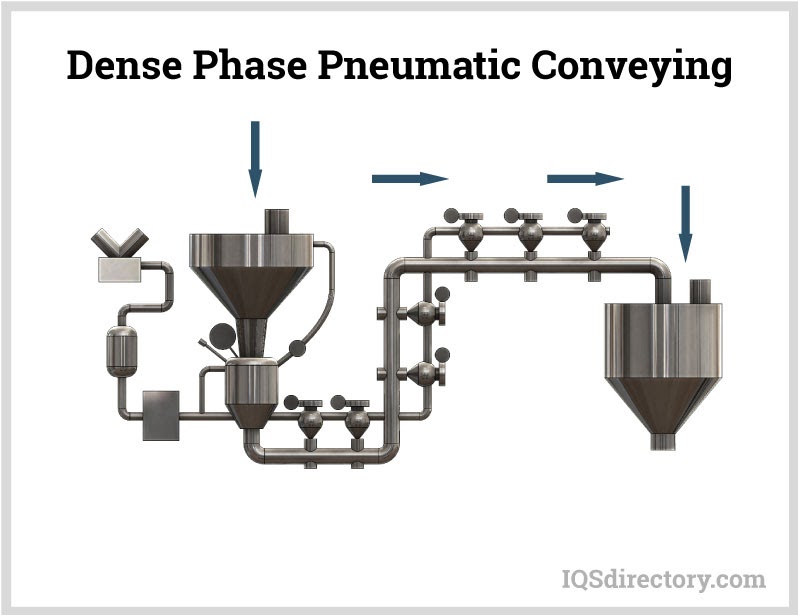

Pneumatic Conveyor

Pneumatic conveyors facilitate the movement of bulk materials, especially powdered solids. These systems operate within enclosed pipelines and include components such as a feeder, air mover, termination vessel, dust collection system, and belt conveyor. They primarily use air, though sometimes gas, as the medium for conveying. When gas is employed, the system leverages a combination of pressure differentials and the flow of gasses like nitrogen.

Screw Conveyor

Screw conveyors transport materials by utilizing a rotating screw within an enclosed linear space. This screw also functions as a mixer or agitator. While unsuitable for sticky substances, screw conveyors effectively handle a variety of semi-dry and dry bulk materials, including cocoa beans, animal feed, garlic powder, carbon black, flour, gypsum, grain, Epsom salt, and whey. These conveyors can be oriented either vertically or horizontally. Vertical screw conveyors are particularly advantageous for heavy-duty tasks and applications with space constraints.

Modular Conveyor Systems

One of the major benefits of a modular conveyor is its mobility and complete flexibility in both construction and reconfiguration. Additionally, there are many other reasons why modular conveyors are superior to custom-built conveyor systems.

- Conveyor modules are crafted from lightweight, durable, high-impact polycarbonate, creating a portable belt conveyor system that is easy to install and transport.

- Modular conveyors can be used with a variety of plastic link belts and different types of drive flights (cleats), making them suitable for many parts conveying applications.

- Modular conveyor systems can be tailored to your needs by combining horizontal, radius turn, angular decline, and incline modules. Quickly reconfigure your existing setup as your requirements evolve, saving both time and money.

Benefits of Conveyor Systems

Conveyor systems bring significant advantages to various industries, enhancing efficiency, productivity, and safety. They streamline operations by automating material handling, ensuring a steady and reliable flow of goods. This automation cuts down on manual labor, reducing associated costs and minimizing the potential for human error. Moreover, these systems enhance productivity by enabling faster and more consistent throughput. They ensure a smooth flow of materials or products, reducing bottlenecks and optimizing the entire production or distribution process.

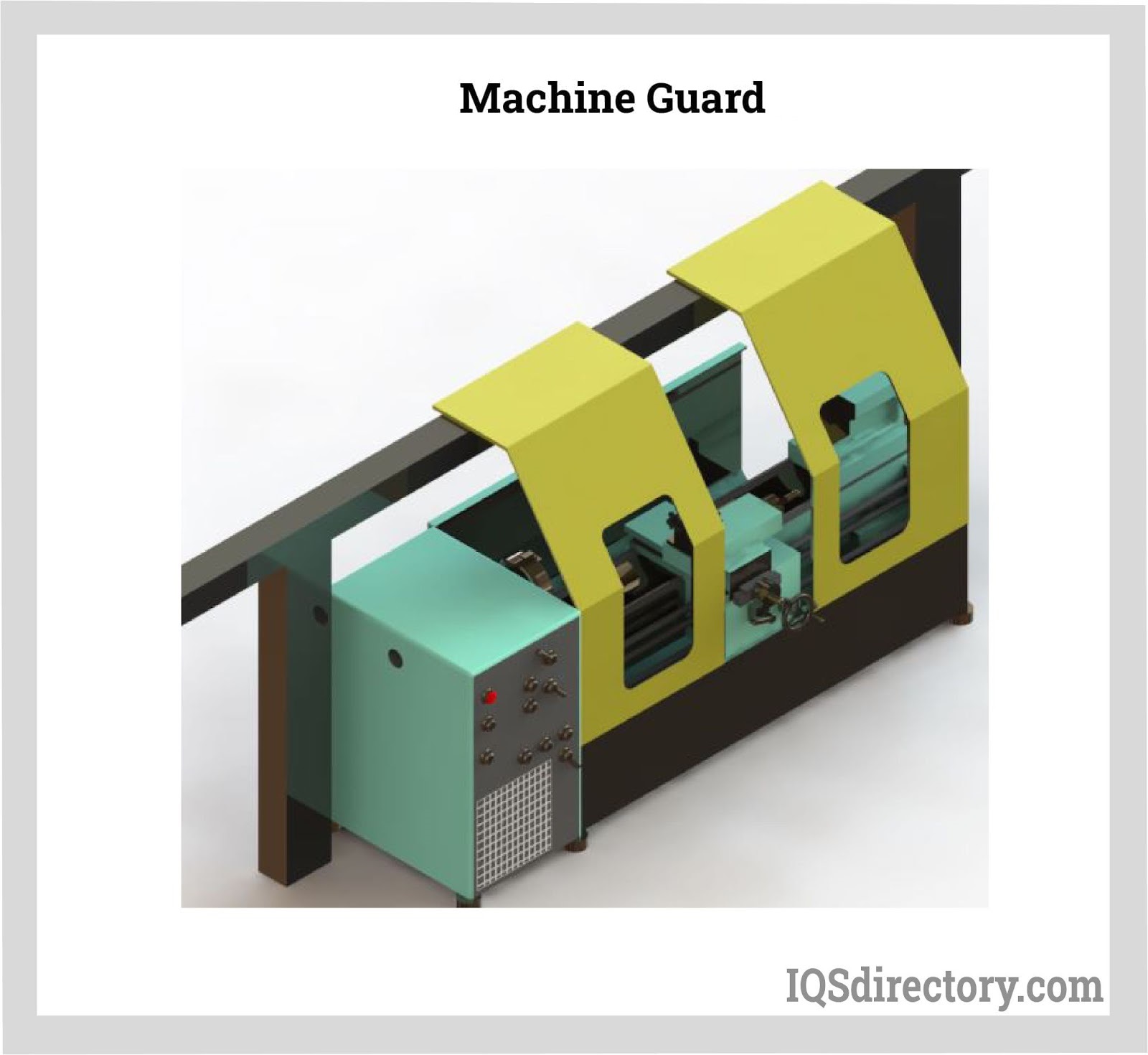

Conveyor systems enhance workplace safety by reducing manual handling and the risks of lifting and carrying heavy items. By automating material transport, these systems lessen the physical strain on workers, creating a safer work environment. Conveyor systems can also include safety features like emergency stop buttons, sensors, and guards to prevent accidents and protect operators.

Another advantage of conveyor systems is their capability to enhance space utilization. These systems can be tailored to match the facility’s layout, including vertical or inclined setups, ensuring efficient use of available space. This is especially beneficial in warehouses and distribution centers where maximizing storage capacity is essential.

Conveyor systems significantly enhance accuracy and product quality. By allowing precise movement and positioning of goods, they minimize the risk of damage or errors during transport. Automated sorting and diverting mechanisms further improve accuracy, ensuring products are correctly directed to their designated destinations.

Additionally, conveyor systems enhance inventory management and traceability. Integrating barcode or RFID scanning technologies allows for tracking and monitoring items as they move along the conveyor. This supports real-time inventory control, minimizes the risk of stockouts or overstocking, and improves traceability for quality control or recall needs.

In summary, conveyor systems offer numerous advantages, such as boosting operational efficiency, elevating productivity, enhancing workplace safety, maximizing space utilization, and ensuring better accuracy and traceability. These benefits make them essential for industries aiming to streamline material handling and achieve greater efficiency and effectiveness.

Conveyor System Design and Customization

Conveyors can be engineered to bend, twist, and ascend along surfaces. Manufacturers have the capability to craft bespoke conveyors that elevate, sort, redirect, and navigate items across both horizontal and vertical planes. They can also design these conveyors to be portable and modular, allowing for straightforward disassembly and reassembly.

When designing and customizing conveyor systems, manufacturers consider several factors, with the primary focus being the application’s requirements. They determine whether the system is meant for simple transportation or as part of a more complex assembly or packaging operation. The type of materials to be conveyed plays a crucial role: Are they items that need to remain sanitary, like food or medicine? Are they loose products like nuts and bolts, or perhaps a powder? Understanding the nature of the materials or products informs decisions regarding the type of conveyor system, belt material, power source (whether electric, gravity, or inertia), and movement mechanism.

Conveyor System Safety and Compliance Standards

The safety and compliance standards for your conveyor system hinge on your specific application, industry, and location. For instance, conveyors used in food processing must adhere to FDA regulations, while those transporting military parts must comply with Mil-Specs. In the United States, organizations like ANSI, CEMA, ASME, and ISO offer detailed standards for various conveyor types and their applications.

How to Choose the Right Conveyor System Manufacturer

There are numerous conveyor system manufacturers available. Although a quick Google search might suffice for some needs, it isn’t always the most effective or convenient method for finding a quality supplier for such a critical task. To assist you in this effort, we’ve compiled a list of trusted companies, complete with detailed profiles. Each company listed here is both experienced and reliable.

We understand you can’t collaborate with every option available. So, how do you decide? Start by listing your specifications. Consider what your system will handle: Are the items heavy, loose, food-related, medicinal, or combustible? Reflect on the entire operation: Does it require cleaning, assembly, or any other processes? Does it need to cover long distances or navigate curves? Next, evaluate your budget, timeline, delivery preferences, and post-manufacturing needs like installation assistance. Jot down any questions. To ensure thoroughness, review your list with a colleague. Once your list is complete, explore the companies on our page. Examine their profiles to identify those offering services aligned with your needs. Select your top three or four, then reach out to each.

Discuss all the points on your list with them and compare the feedback. When choosing a conveyor system manufacturer, look for both expertise and excellent customer service. You want a partner committed to providing the best solutions. Identify the manufacturer that meets your criteria and begin your project.

Conveyor Belting

Conveyor Belting Conveyor Systems

Conveyor Systems Conveyors

Conveyors Hosereels

Hosereels Industrial Lubricants

Industrial Lubricants Lubricators

Lubricators Screw Conveyors

Screw Conveyors Pneumatic Conveyors

Pneumatic Conveyors AGV

AGV Air Pollution Control

Air Pollution Control Assembly Machinery

Assembly Machinery Blowers

Blowers Cranes

Cranes Deburring Machinery

Deburring Machinery Dust Collectors

Dust Collectors Heaters

Heaters Hose Reels

Hose Reels Mezzanines

Mezzanines Modular Buildings

Modular Buildings Storage Racks

Storage Racks Ultrasonic Cleaners

Ultrasonic Cleaners Work Benches

Work Benches