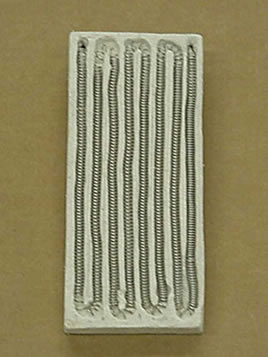

This conveyor also features a chain or cable, a long pipe and discs, also known as “pucks.” The chain runs through the pipe and the pucks, sized so they fit snugly to the pipe, are connected to the chain. To work, the pucks pick up material as they drag along the walls of the pipe, pulled by the chain. Read More…

VAC-U-MAX is a premier manufacturer of quality conveyors among other similar products and services. VAC-U-MAX produces its equipment to handle small parts and heavy metal powders.

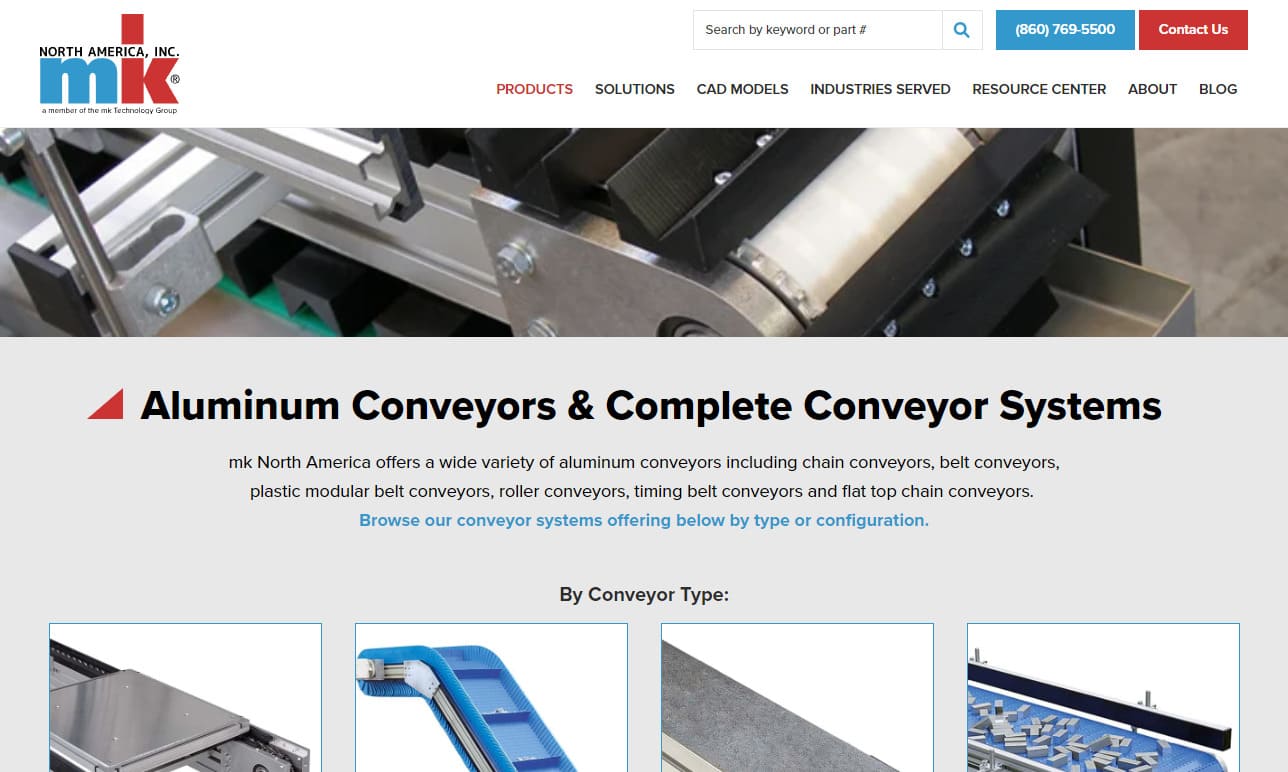

mk North America, Inc. offers the widest variety of conveyors in the industry. Our vast product line features a variety of aluminum frame and stainless-steel conveyors that are built to last. At mk we believe in offering not only a better product, but also a better solution – which is why we will work with you to ensure your unique application is matched with the best possible conveyor...

At Slate River Systems Inc, we take pride in our expertise as innovators in the field of conveyor systems. With years of collective experience, our team is committed to delivering cutting-edge solutions tailored to meet the diverse needs of our clients. Our conveyor systems are engineered to optimize efficiency and streamline material handling processes across various industries.

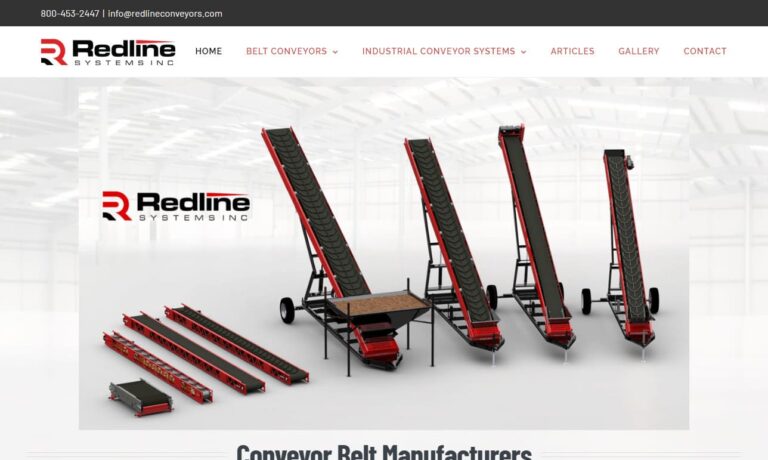

Redline Systems, Inc. is a leading provider of innovative conveyor solutions. They offer various conveyor types, including portable belt conveyors, incline conveyors, horizontal conveyors, stainless conveyors, and more. Experience the difference with Redline Systems, where innovation meets reliability in conveyor technology.

Impact Automation stands as a prominent force in the field of automation, specializing in the design and implementation of advanced conveying systems tailored for diverse manufacturing processes. With a focus on efficiency, precision, and adaptability, we offer a comprehensive product range that includes sorter feed systems, sorter solutions, traditional conveyors, and plastic belt conveyors.

Spiroflow offers a complete range of mechanical conveying solutions in the industry. The staff at Spiroflow can recommend the best method to meet your conveying needs.

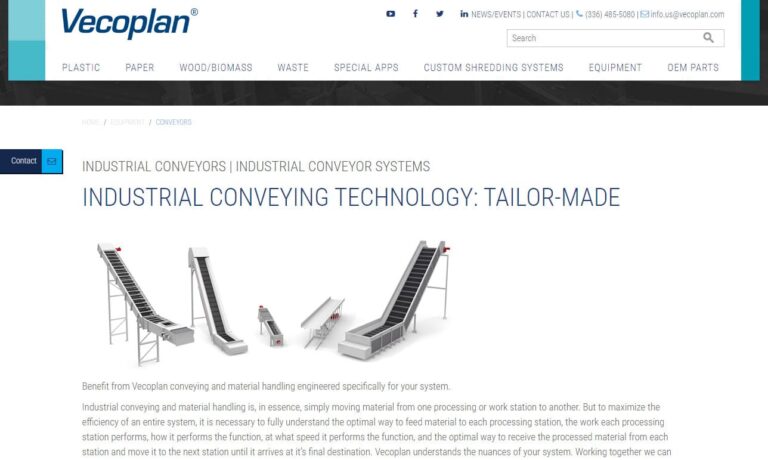

Vecoplan leads the charge with cutting-edge technologies that revolutionize waste and recycling. From versatile shredders and granulators to efficient conveying and sorting systems, Vecoplan offers a wide array of solutions for handling wood, paper, plastics, textiles, and more. Our tailored equipment sets new industry standards, meeting the demands of even the most challenging applications.

More Drag Chain Conveyor Manufacturers

To ensure that any material that what one puck drops, another will sweep up, conveyors feature several, if not hundreds of these pucks. Pucks may be made of metal or a synthetic material, such as plastic, and they are generally spaced out several inches to feet apart to allow for adequate storage space. The chain is flexible, making it possible to guide materials around the corner of the pipe, if necessary.

The material with which a drag chain conveyor is made depends largely on what materials it will be handling. Generally, for conveyors moving materials that are corrosive or contaminable, stainless steel or an abrasion-resistant alloy will be the likely choice. For less sensitive materials, an inexpensive option is carbon steel. Materials that drag chain conveyor may transport include: alumina, dry ash, finished cement, bituminous coal, fertilizers, grains, limestone, malt, food meal, petroleum coke, phosphate rock, salt cake, dense soda ash, silica/quartz sand, sized wood chips, urea and calcined zinc.

It is important that these materials are small, because drag chain conveyors are not appropriate for transporting larger items. In fact, they will likely jam if larger objects are placed inside them. Both chains and cables may be used with this system, but cables require regular inspections to check for frays, because they could lead to system failure.

Well maintained drag chain conveyors offer many advantages to manufacturers. First, their total enclosure ensures dust and contaminant-free handling, which promotes worker health and wellbeing. Second, drag chain conveyors are the only industrial conveyors on the market that can operate in three planes. This eliminates transfer points, permits complex circuits and allows operators to use only a single drive. In addition, when compared to other conveyors, drag chain conveyors use minimum horsepower and have an overall lower level of energy consumption. They also have a minimum noise level and gentle conveying action that reduces product degradation.

Conveyor Belting

Conveyor Belting Conveyor Systems

Conveyor Systems Conveyors

Conveyors Hosereels

Hosereels Industrial Lubricants

Industrial Lubricants Lubricators

Lubricators Screw Conveyors

Screw Conveyors Pneumatic Conveyors

Pneumatic Conveyors AGV

AGV Air Pollution Control

Air Pollution Control Assembly Machinery

Assembly Machinery Blowers

Blowers Cranes

Cranes Deburring Machinery

Deburring Machinery Dust Collectors

Dust Collectors Heaters

Heaters Hose Reels

Hose Reels Mezzanines

Mezzanines Modular Buildings

Modular Buildings Storage Racks

Storage Racks Ultrasonic Cleaners

Ultrasonic Cleaners Work Benches

Work Benches