A conveyor’s specific function, however, varies greatly according to the type of materials it is designed to transport. For example, some industrial conveyors are powered by electric motors, while others work completely without electricity, and require an operator to keep the system running. Furthermore, some systems are portable and may be broken down and reassembled quickly and easily. Read More…

VAC-U-MAX is a premier manufacturer of quality conveyors among other similar products and services. VAC-U-MAX produces its equipment to handle small parts and heavy metal powders.

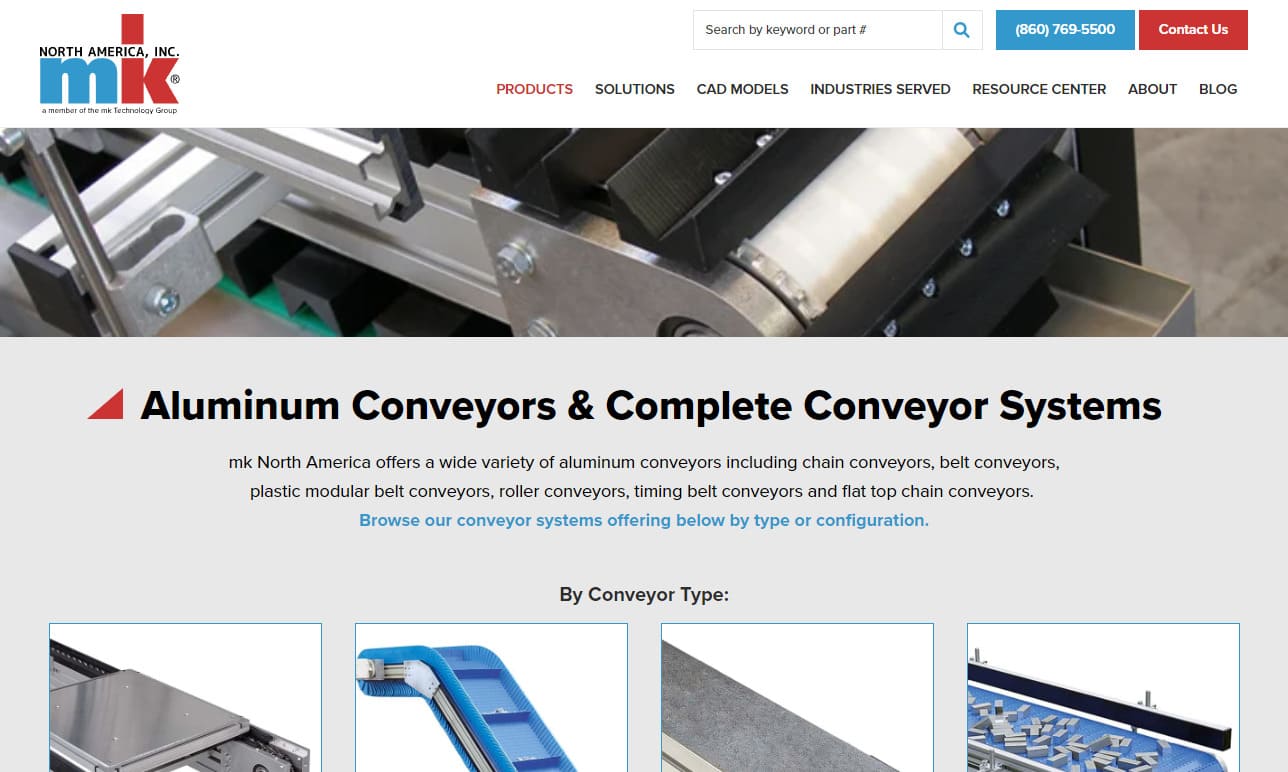

mk North America, Inc. offers the widest variety of conveyors in the industry. Our vast product line features a variety of aluminum frame and stainless-steel conveyors that are built to last. At mk we believe in offering not only a better product, but also a better solution – which is why we will work with you to ensure your unique application is matched with the best possible conveyor...

At Slate River Systems Inc, we take pride in our expertise as innovators in the field of conveyor systems. With years of collective experience, our team is committed to delivering cutting-edge solutions tailored to meet the diverse needs of our clients. Our conveyor systems are engineered to optimize efficiency and streamline material handling processes across various industries.

Redline Systems, Inc. is a leading provider of innovative conveyor solutions. They offer various conveyor types, including portable belt conveyors, incline conveyors, horizontal conveyors, stainless conveyors, and more. Experience the difference with Redline Systems, where innovation meets reliability in conveyor technology.

Impact Automation stands as a prominent force in the field of automation, specializing in the design and implementation of advanced conveying systems tailored for diverse manufacturing processes. With a focus on efficiency, precision, and adaptability, we offer a comprehensive product range that includes sorter feed systems, sorter solutions, traditional conveyors, and plastic belt conveyors.

Spiroflow offers a complete range of mechanical conveying solutions in the industry. The staff at Spiroflow can recommend the best method to meet your conveying needs.

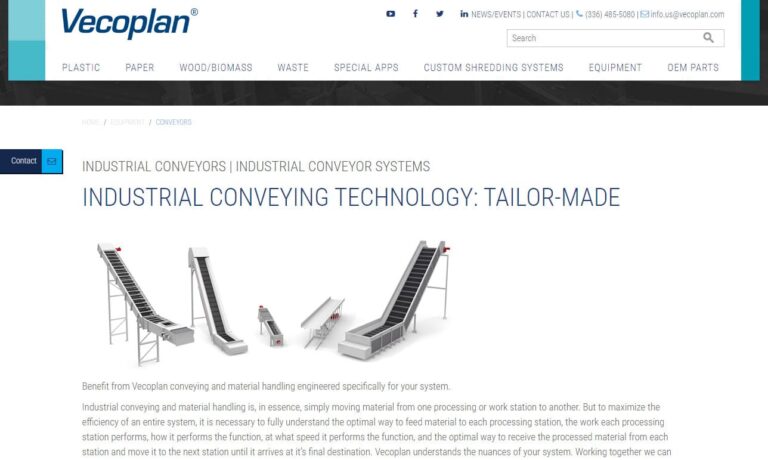

Vecoplan leads the charge with cutting-edge technologies that revolutionize waste and recycling. From versatile shredders and granulators to efficient conveying and sorting systems, Vecoplan offers a wide array of solutions for handling wood, paper, plastics, textiles, and more. Our tailored equipment sets new industry standards, meeting the demands of even the most challenging applications.

More Industrial Conveyor Manufacturers

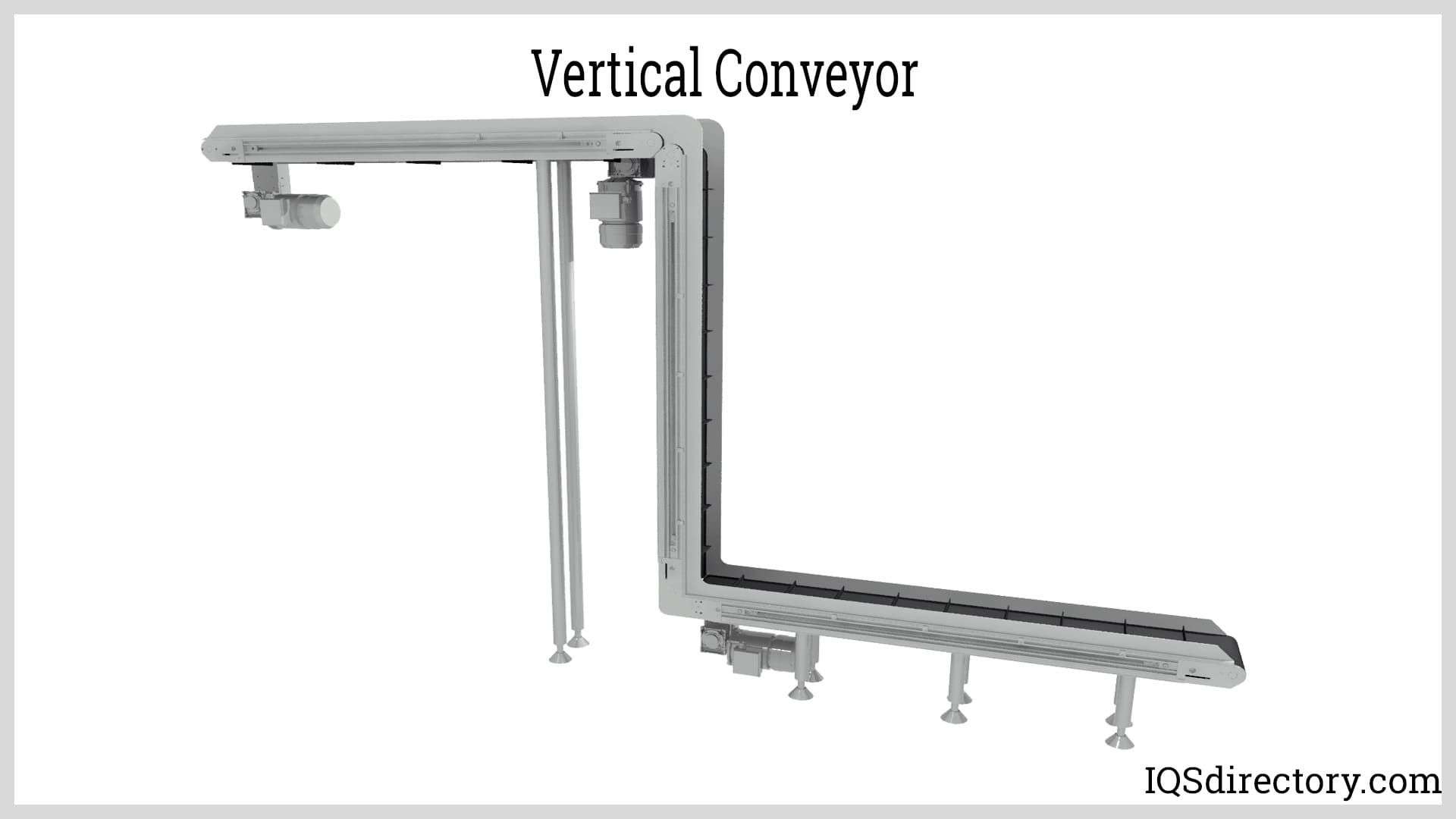

Two types of well-known industrial conveyors are belt conveyors and auger conveyors. Belt conveyor systems function using a rubberized belt that is wrapped around a series of rollers, some of which are connected to a motor that turns the rollers. After the motor turns the rollers, the rollers move the belt. Said belt, which is sometimes replaced with a metal chain belt or a plastic belt, must be tensioned properly in order to make sure it runs smoothly. If not, the belt may get caught on one or more components within the system. The next common industrial conveyor, the auger conveyor, features a large screw blade or auger that is contained within the system, usually inside a tube.

As the auger conveyor turns, those contents in the conveyor are propelled forward along the length of the system. Contents of an auger conveyor are usually some form of fine particulate, grain or semi-solid material. These materials include: wood waste, wood chips, aggregates, cereal grains, animal feed, boiler ash, meat and bone meal and municipal solid waste. This system requires that the belt be laid flat or at a slight angle only in a straight line, because the auger or screw itself must be straight.

Some industrial conveyors are required to run around corners or in other non-linear fashions. These industrial conveyors usually operate using a drag chain system. In this case, the conveyor contains a long cable or chain to which discs are attached. The cable or chain will pull the discs through the chamber where, in between each disc, material is loaded and pulled along through the system. In this system, there is little or no clearance between the discs and the side walls of the chamber, which prevents material from backsliding. For this reason, discs must be made from a durable material that will not succumb to friction. Consumer standard and custom options for industrial conveyors are nearly endless and those that are well-chosen and well-maintained will no doubt serve their purpose well for many years.

Conveyor Belting

Conveyor Belting Conveyor Systems

Conveyor Systems Conveyors

Conveyors Hosereels

Hosereels Industrial Lubricants

Industrial Lubricants Lubricators

Lubricators Screw Conveyors

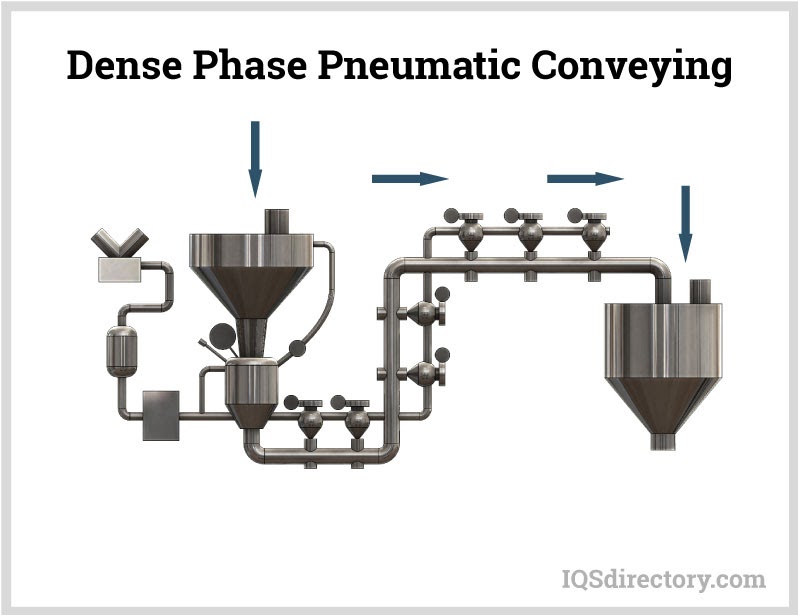

Screw Conveyors Pneumatic Conveyors

Pneumatic Conveyors AGV

AGV Air Pollution Control

Air Pollution Control Assembly Machinery

Assembly Machinery Blowers

Blowers Cranes

Cranes Deburring Machinery

Deburring Machinery Dust Collectors

Dust Collectors Heaters

Heaters Hose Reels

Hose Reels Mezzanines

Mezzanines Modular Buildings

Modular Buildings Storage Racks

Storage Racks Ultrasonic Cleaners

Ultrasonic Cleaners Work Benches

Work Benches