Conveyors are an important part of many industries, as they have made the transport of heavy and bulky objects easy and efficient. An overhead conveyor is a type of conveying system that is unique because it operates from over the heads of workers and equipment. These conveyors are ideal in industries that benefit from saving floor space. Read More…

VAC-U-MAX is a premier manufacturer of quality conveyors among other similar products and services. VAC-U-MAX produces its equipment to handle small parts and heavy metal powders.

mk North America, Inc. offers the widest variety of conveyors in the industry. Our vast product line features a variety of aluminum frame and stainless-steel conveyors that are built to last. At mk we believe in offering not only a better product, but also a better solution – which is why we will work with you to ensure your unique application is matched with the best possible conveyor...

At RMH Systems, we specialize in crafting innovative conveyor systems that streamline operations and maximize efficiency for a wide range of industries. Our expertly designed conveyor solutions are tailored to meet the unique needs of each client, ensuring seamless integration into existing processes.

At Slate River Systems Inc, we take pride in our expertise as innovators in the field of conveyor systems. With years of collective experience, our team is committed to delivering cutting-edge solutions tailored to meet the diverse needs of our clients. Our conveyor systems are engineered to optimize efficiency and streamline material handling processes across various industries.

Many types, sizes, makes & models of shelving available online at SJF.com. We buy & sell warehouse equipment with the nation's largest inventory of new and used material handling equipment: over 20 acres! Explore our website & find dealer direct savings on shelving & more types of material handling equipment.

Spiroflow offers a complete range of mechanical conveying solutions in the industry. The staff at Spiroflow can recommend the best method to meet your conveying needs.

If you are in need of conveyors that are built to last, you can count on us to be your number one provider. We manufacture conveyors that guarantee efficiency and stability. Our teams offer fast turnaround on all orders and if an issue ever arises then we will work with you to quickly repair your systems. Give us a call today or visit our website to learn more information!

More Overhead Conveyor Manufacturers

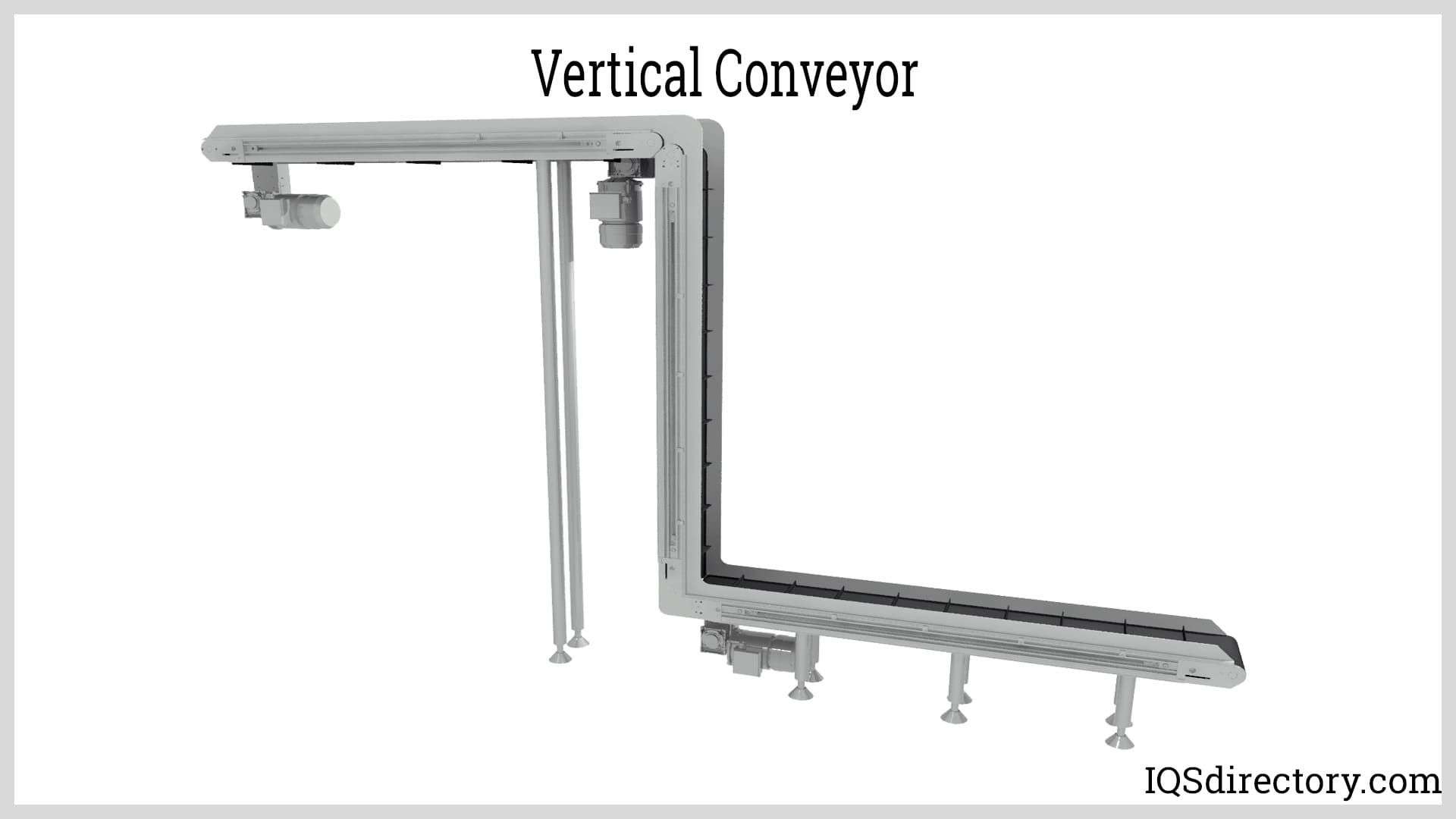

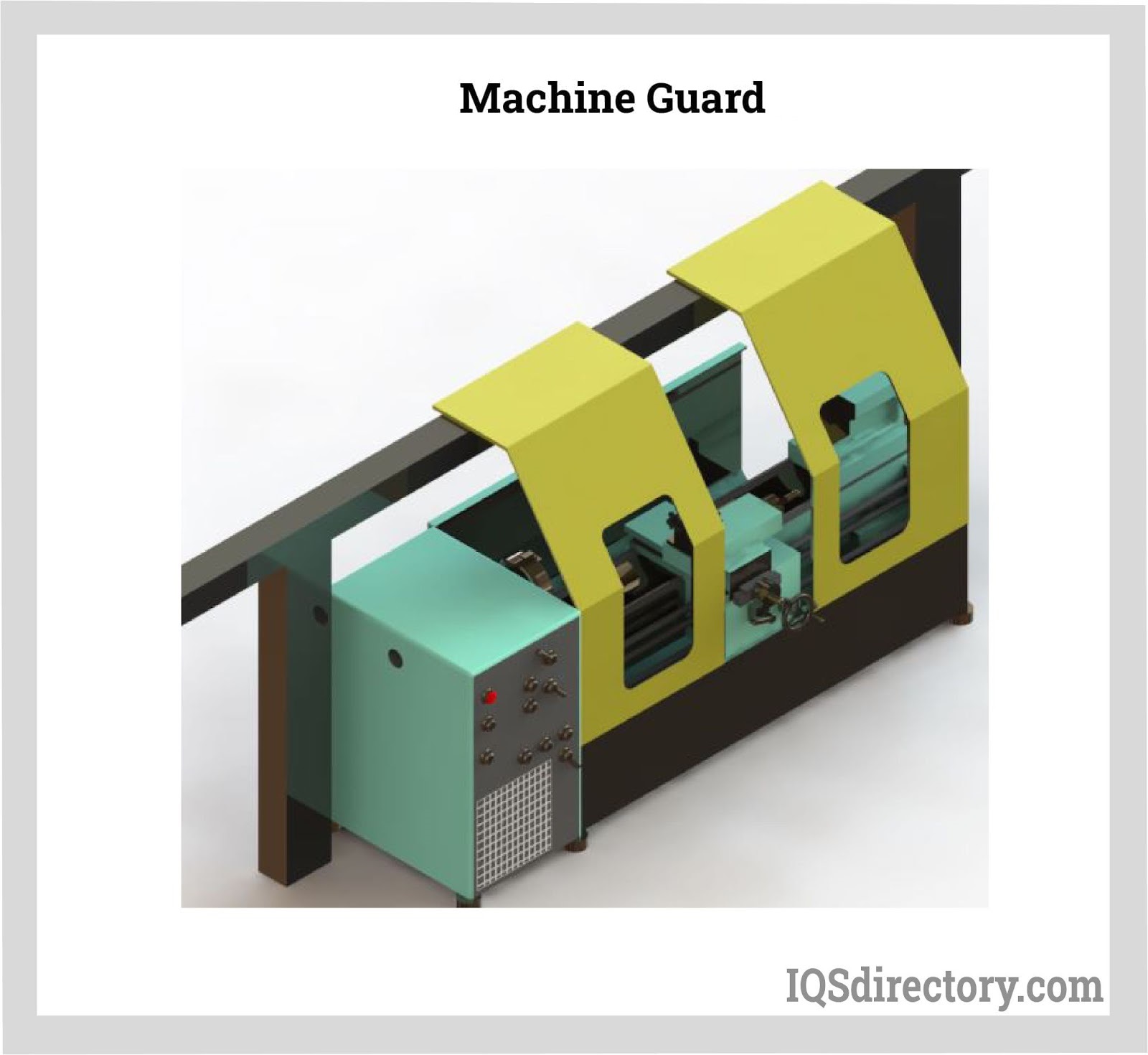

An overhead conveyor is an elevated system, but it is not belt driven. Instead, thin chains are used to move suspended trolleys holding items. These trolleys take the form of hooks or rings, and they can hold a considerable amount of weight. The conveyor chain transports the materials from one place to another in a loop. It can be manually operated or motorized.

The tracks and carriers are simply designed and can be changed into any form the application needs. Overhead conveyors need to be monitored and checked from time to time to avoid any accidents in the workplace.

Specifications and Selection Criteria

There are certain specifications to consider while installing an overhead conveyor in the work area. These specifications include the maximum load the conveyor has to carry, the load geometry, and the capacity of the load to be transported. Other factors are the speed and distance of the conveyor, and whether any bends are needed throughout the conveyor’s path. In addition, overhead conveyors work best in milder environments because humid and corrosive conditions can affect the working of an overhead conveyor.

Working of Overhead Conveyors

Overhead conveyors have chains instead of belts for material movement. They free up considerable floor space by functioning above the work area. An overhead conveyor uses a continuous track that is suspended with the help of pendants, or support present on the track. These pendants helps to keep the materials in place. The pendants are designed according to the application and capacity requirements; they accommodate all types of items from light products to heavy duty parts.

Types of Overhead Conveyors

There are three types of overhead conveyors, and each has a specific design and function. These are:

Enclosed Track And Open Track Conveyors

- Overhead conveyor tracks can be differentiated into two types: enclosed track and monorail open track.

- The enclosed tracks are less likely to be damaged by environmental decay and can prevent excess damage to the track. They are often used in areas where paints can damage the tracks.

- Open rail tracks are simpler, easy to install, and use trolleys instead of chains.

- Open rail tracks can convey more items and are more suited for applications where bends are required in the path.

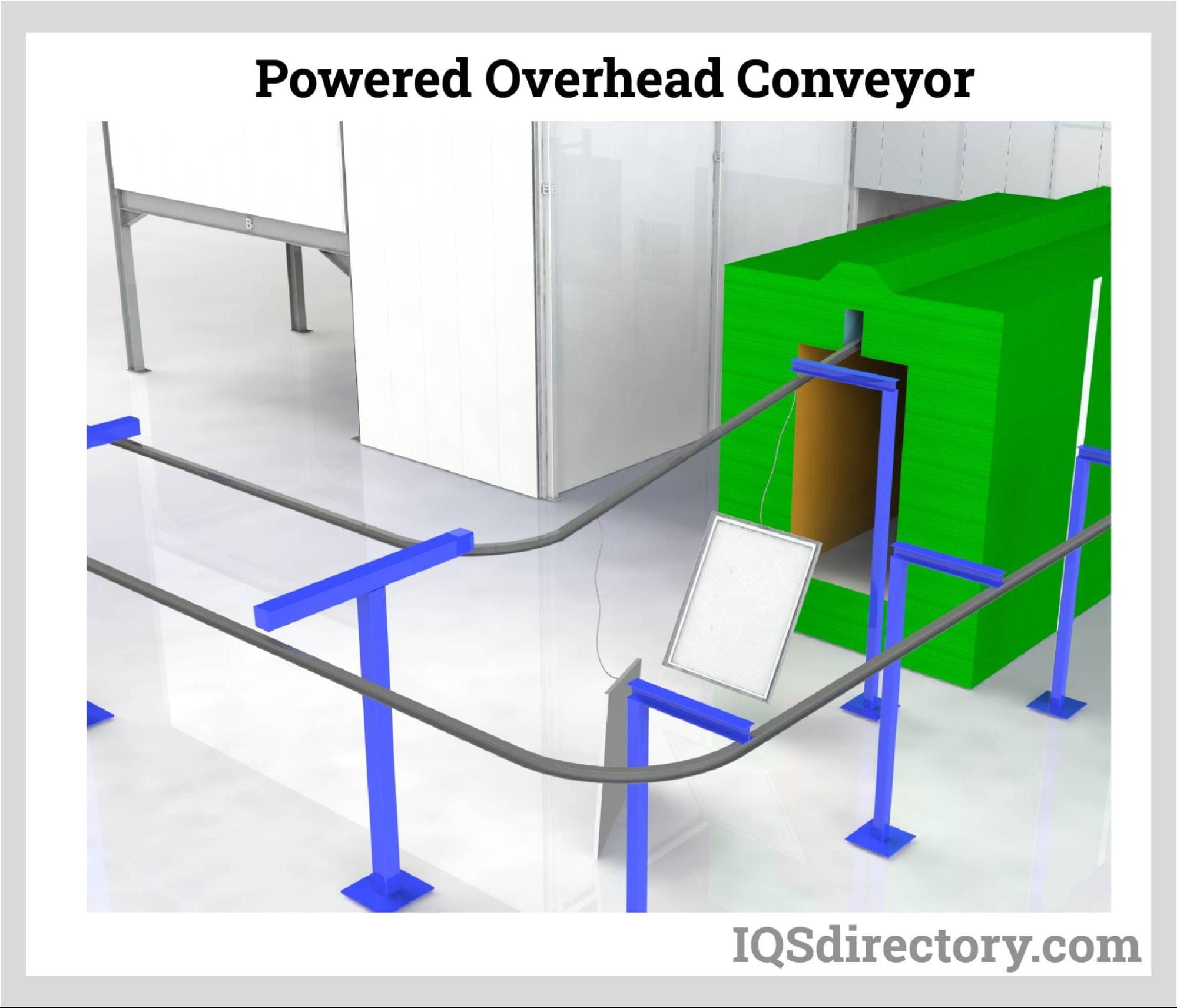

Powered And Free Overhead Conveyor

- Overhead conveyors can either be motor powered or free to move.

- Powered overhead conveyors are ideal for reducing labor and improving efficiency.

- However, free overhead conveyors are more economical, though labor is required for pushing and pulling of the material.

Synchronous And Asynchronous Conveyor

- Synchronous overhead conveyors are used to make sure there is an equal space and distance between the conveying items and no intermingling.

- The powered, controlled synchronization helps in avoiding accidents or damage to the items conveyed.

- In a synchronous conveyor, the operator has full command over the conveying system.

- The asynchronous overhead conveyors are typically unpowered and the items are allowed to move independently.

Applications of Overhead Conveyors

- Overhead conveyors are used in the painting and cleaning industries.

- Overhead conveyors are also used in industries for conveying empty cartons to the operator more quickly.

- Packing industry also use overhead conveyors to quickly convey materials.

- Other industries such as automotive, pharmaceutical, food, greenhouse and many more are using overhead conveyors to complete their processes in no time.

Benefits of Overhead Conveyors

Overhead conveyors are the most efficient solution to a variety of applications and processes.

- Overhead conveyors greatly free up floor space.

- They reduce the travel time of goods.

- They improve ergonomics by reducing lifting and bending for assembly processes.

Choosing the Correct Overhead Conveyors Manufacturer

To make sure you have the most constructive outcome when purchasing Overhead Conveyors from an Overhead Conveyors Company, it is important to compare at least 5 or 6 Companies using our list of Overhead Conveyors manufacturers. Each Overhead Conveyors Supplier has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each Overhead Conveyors business website using our proprietary website previewer to get an idea of what each business specializes in, and then use our simple RFQ form to contact multiple Overhead Conveyors companies with the same form.

Conveyor Belting

Conveyor Belting Conveyor Systems

Conveyor Systems Conveyors

Conveyors Hosereels

Hosereels Industrial Lubricants

Industrial Lubricants Lubricators

Lubricators Screw Conveyors

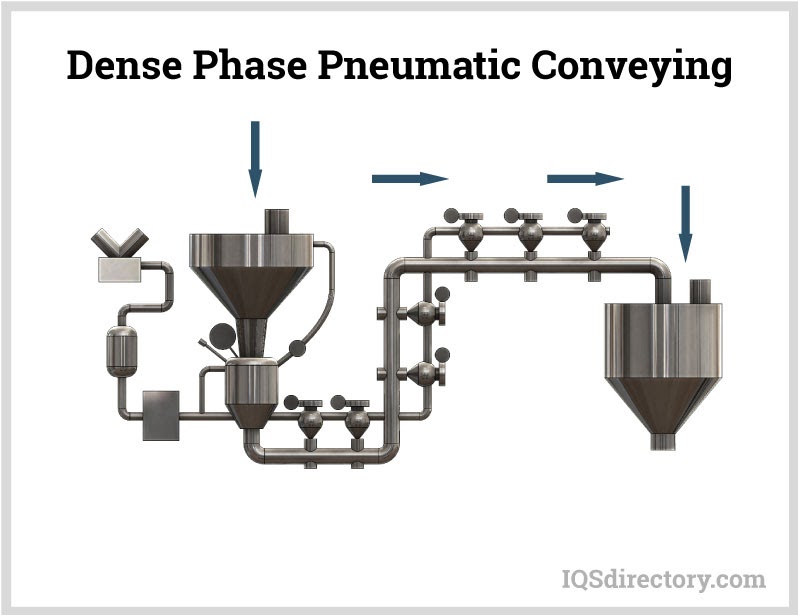

Screw Conveyors Pneumatic Conveyors

Pneumatic Conveyors AGV

AGV Air Pollution Control

Air Pollution Control Assembly Machinery

Assembly Machinery Blowers

Blowers Cranes

Cranes Deburring Machinery

Deburring Machinery Dust Collectors

Dust Collectors Heaters

Heaters Hose Reels

Hose Reels Mezzanines

Mezzanines Modular Buildings

Modular Buildings Storage Racks

Storage Racks Ultrasonic Cleaners

Ultrasonic Cleaners Work Benches

Work Benches