These conveyors efficiently move boxes, packages, products, materials and parts that have flat bottoms and are heavy to lift. The ball sizes are usually comparable to pool balls and are made of either steel or nylon depending on the fragility of the products being moved. Read More…

VAC-U-MAX is a premier manufacturer of quality conveyors among other similar products and services. VAC-U-MAX produces its equipment to handle small parts and heavy metal powders.

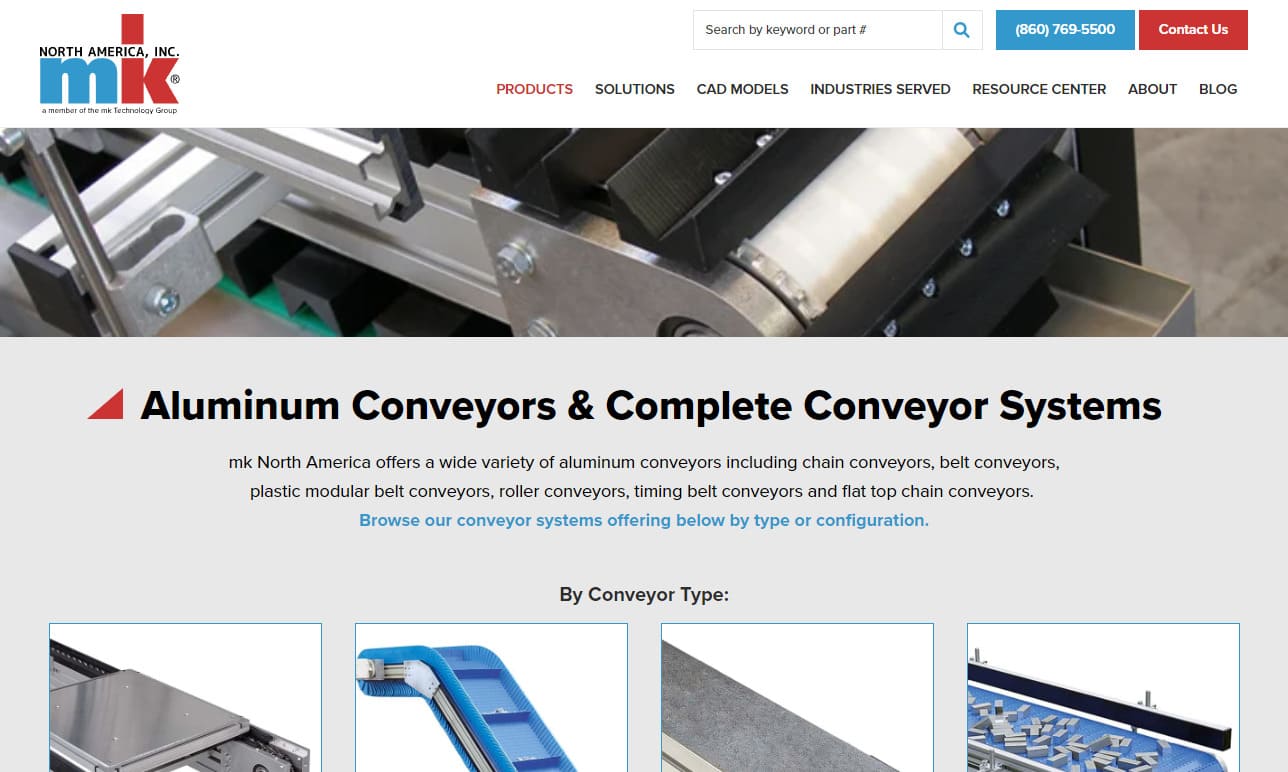

mk North America, Inc. offers the widest variety of conveyors in the industry. Our vast product line features a variety of aluminum frame and stainless-steel conveyors that are built to last. At mk we believe in offering not only a better product, but also a better solution – which is why we will work with you to ensure your unique application is matched with the best possible conveyor...

At Slate River Systems Inc, we take pride in our expertise as innovators in the field of conveyor systems. With years of collective experience, our team is committed to delivering cutting-edge solutions tailored to meet the diverse needs of our clients. Our conveyor systems are engineered to optimize efficiency and streamline material handling processes across various industries.

Redline Systems, Inc. is a leading provider of innovative conveyor solutions. They offer various conveyor types, including portable belt conveyors, incline conveyors, horizontal conveyors, stainless conveyors, and more. Experience the difference with Redline Systems, where innovation meets reliability in conveyor technology.

Impact Automation stands as a prominent force in the field of automation, specializing in the design and implementation of advanced conveying systems tailored for diverse manufacturing processes. With a focus on efficiency, precision, and adaptability, we offer a comprehensive product range that includes sorter feed systems, sorter solutions, traditional conveyors, and plastic belt conveyors.

Spiroflow offers a complete range of mechanical conveying solutions in the industry. The staff at Spiroflow can recommend the best method to meet your conveying needs.

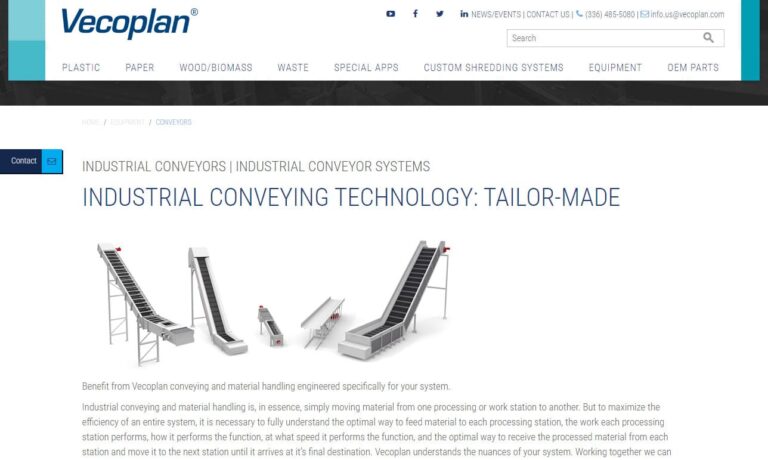

Vecoplan leads the charge with cutting-edge technologies that revolutionize waste and recycling. From versatile shredders and granulators to efficient conveying and sorting systems, Vecoplan offers a wide array of solutions for handling wood, paper, plastics, textiles, and more. Our tailored equipment sets new industry standards, meeting the demands of even the most challenging applications.

More Ball Transfer Conveyor Manufacturers

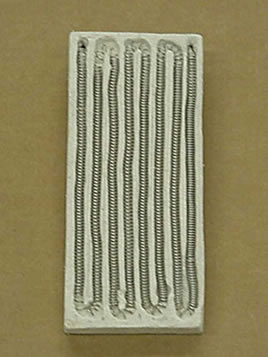

Within Ball Transfer Conveyors, each ball sits atop smaller balls, which are encased in a cup and may hold about 50 pounds at a time. Ball transfer conveyors may stand alone as a transfer unit between conveyors or a table. Ball transfer tables are used at workstations for rotating the products being manufactured in any direction. They may also serve as a component in a large conveyor handling system. Presses, guillotines, assembly lines, warehouses, factories, manufacturing and packaging facilities and The Postal Service all use ball transfer conveyors, especially when the products being moved need to rotate or turn easily. They may be easily washed down, and are chemical, water and erosion resistant.

Ball transfer conveyors utilize metallic balls in order to facilitate the material handling process. Because the products and packages that ball transfer conveyors move tend to be extremely heavy, the metal balls are commonly manufactured from steel that is often alloyed, case-hardened or treated with black oxide finish for desired characteristics such as increased strength and weight capacity. The balls and casings are easily replaceable and assembled in rails, which may be arranged in different patterns, depending on the specific application and designated route of the transfer system. A circle in the middle allows rotating during transfer, and the ball direction may change directions by forming an L shape.

Ball transfer conveyors that have many balls close together are better-suited for moving heavier objects. The balls are also mounted differently from conveyor to conveyor, and some of the many different mounting styles include: stud, flange, machine press, pipe, round, disk, bolt down and press-in mountings. Ball transfer conveyor systems offer smooth transfer of objects without much friction, which decreases the possibility of wear. Although some manual labor is required, workers simply have to move the boxes and products along without using much force.

Conveyor Belting

Conveyor Belting Conveyor Systems

Conveyor Systems Conveyors

Conveyors Hosereels

Hosereels Industrial Lubricants

Industrial Lubricants Lubricators

Lubricators Screw Conveyors

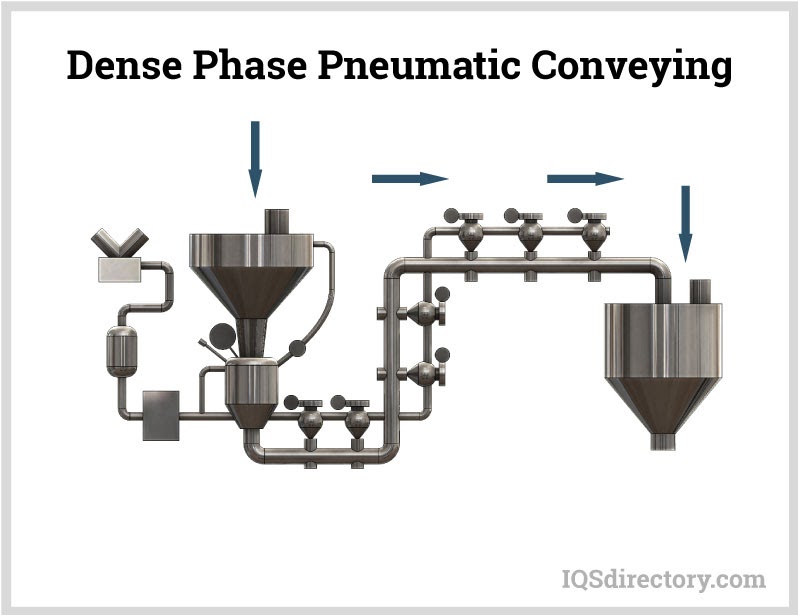

Screw Conveyors Pneumatic Conveyors

Pneumatic Conveyors AGV

AGV Air Pollution Control

Air Pollution Control Assembly Machinery

Assembly Machinery Blowers

Blowers Cranes

Cranes Deburring Machinery

Deburring Machinery Dust Collectors

Dust Collectors Heaters

Heaters Hose Reels

Hose Reels Mezzanines

Mezzanines Modular Buildings

Modular Buildings Storage Racks

Storage Racks Ultrasonic Cleaners

Ultrasonic Cleaners Work Benches

Work Benches