Chain conveyors are continuous and suited for the conveyance of bulk products of all kinds up to small-sized products and sludges. The drive and drive sprockets and sprocket bearings with double-row spherical ball bearings for adjusting and tensioning the transport chain are all parts of the conveyor’s basis. The frame for the conveyor is composed of aluminum grooved section item elements. Read More…

VAC-U-MAX is a premier manufacturer of quality conveyors among other similar products and services. VAC-U-MAX produces its equipment to handle small parts and heavy metal powders.

mk North America, Inc. offers the widest variety of conveyors in the industry. Our vast product line features a variety of aluminum frame and stainless-steel conveyors that are built to last. At mk we believe in offering not only a better product, but also a better solution – which is why we will work with you to ensure your unique application is matched with the best possible conveyor...

At Slate River Systems Inc, we take pride in our expertise as innovators in the field of conveyor systems. With years of collective experience, our team is committed to delivering cutting-edge solutions tailored to meet the diverse needs of our clients. Our conveyor systems are engineered to optimize efficiency and streamline material handling processes across various industries.

Redline Systems, Inc. is a leading provider of innovative conveyor solutions. They offer various conveyor types, including portable belt conveyors, incline conveyors, horizontal conveyors, stainless conveyors, and more. Experience the difference with Redline Systems, where innovation meets reliability in conveyor technology.

Impact Automation stands as a prominent force in the field of automation, specializing in the design and implementation of advanced conveying systems tailored for diverse manufacturing processes. With a focus on efficiency, precision, and adaptability, we offer a comprehensive product range that includes sorter feed systems, sorter solutions, traditional conveyors, and plastic belt conveyors.

Spiroflow offers a complete range of mechanical conveying solutions in the industry. The staff at Spiroflow can recommend the best method to meet your conveying needs.

Vecoplan leads the charge with cutting-edge technologies that revolutionize waste and recycling. From versatile shredders and granulators to efficient conveying and sorting systems, Vecoplan offers a wide array of solutions for handling wood, paper, plastics, textiles, and more. Our tailored equipment sets new industry standards, meeting the demands of even the most challenging applications.

More Chain Conveyor Manufacturers

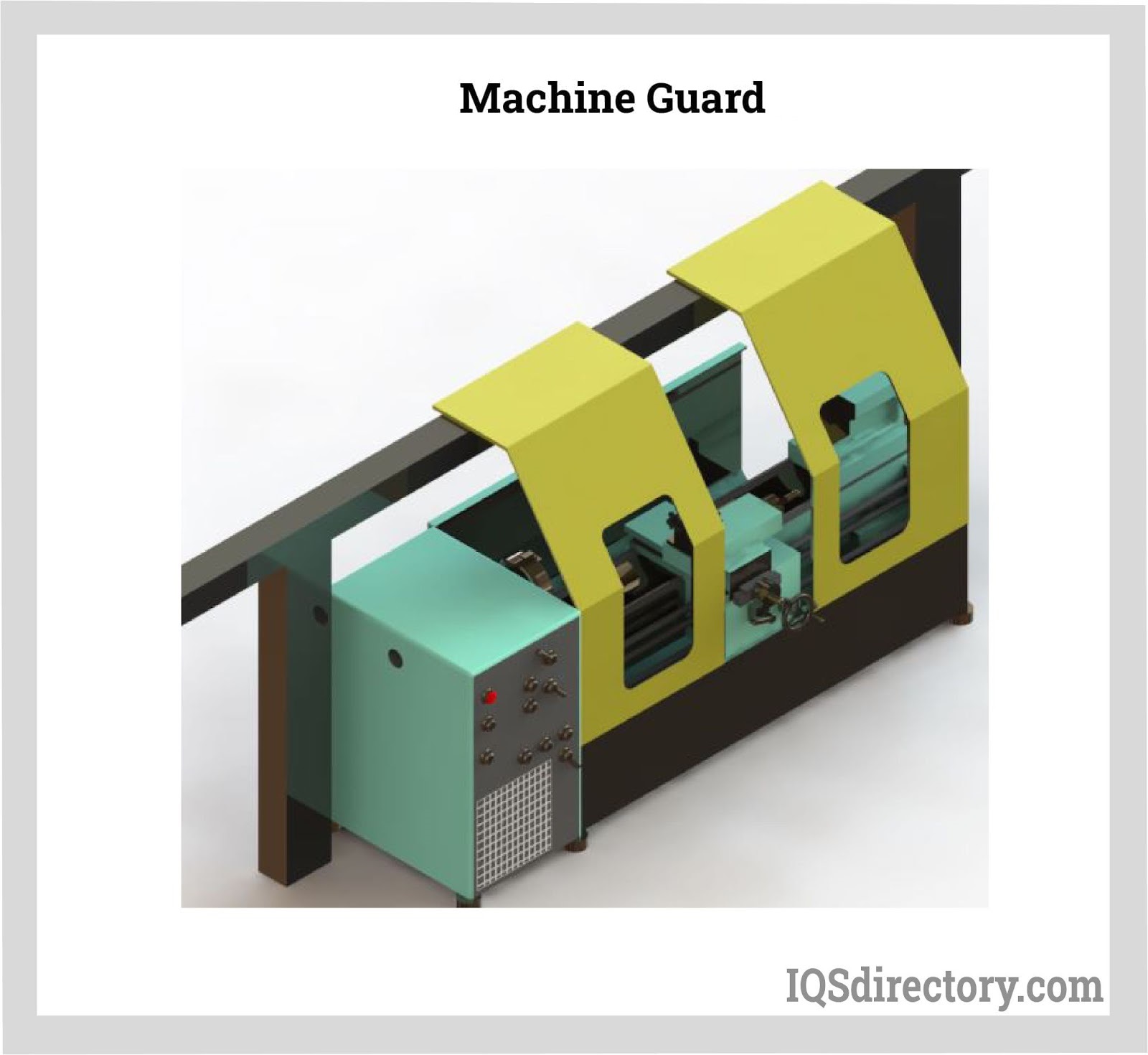

Chain conveyors may carry very wide or very long materials and are principally distinguished by a great performance. The advantages are its excellent temperature resistance (up to 800°C), the low conveying velocities, particularly in the case of abrasive bulk material, and the robust and dustproof design. Chain conveyor technology is used in many industrial sectors for production processes. For instance, chain conveyor systems are used in the automotive industry to move automobile parts through paint factories.

The white- and brown goods, metal-finishing, and distribution sectors employ chain conveyors extensively. The painting and coating business also uses chain conveyors, making painting simpler. In addition, higher productivity is made possible by keeping the products off the floor and attaching them to an above-head chain conveyor.

Working Principle of Chain Conveyors

An infinite chain is used in conveyors to transmit power and push material through a trough, either directly or by attaching it to the chain. At either end of the trough, sprockets are crossed by the chain. The maximum length of a chain conveyor is 90 meters (300 feet), most of which are under 30 meters (98 ft).

Chain conveyors transport many single pendants along a motorized continuous chain configuration. A motor moves the material suspended on pendants along the chain arrangement, and products are moved along an assembly line and or around a production or storage facility.

Types of Chain Conveyors

Drag Conveyors

Drag conveyors are used in bulk material handling to move solid material over a trough. They are also known as drag chain conveyors, scraper chain conveyors, and en-masse conveyors. They are employed in the mining and chemical industries, in municipal solid waste incinerators, and in manufacturing pellet fuel to move materials like cement clinker, ash, and sawdust.

Whether the chain links have evident flights or paddles attached determines how drag conveyors, scraper conveyors, and flight conveyors differ. A flight conveyor uses a succession of wood, metal, or plastic flights attached to the chain at regular intervals to push the material along the trough, as opposed to a drag conveyor, which pushes the material straight along the chain.

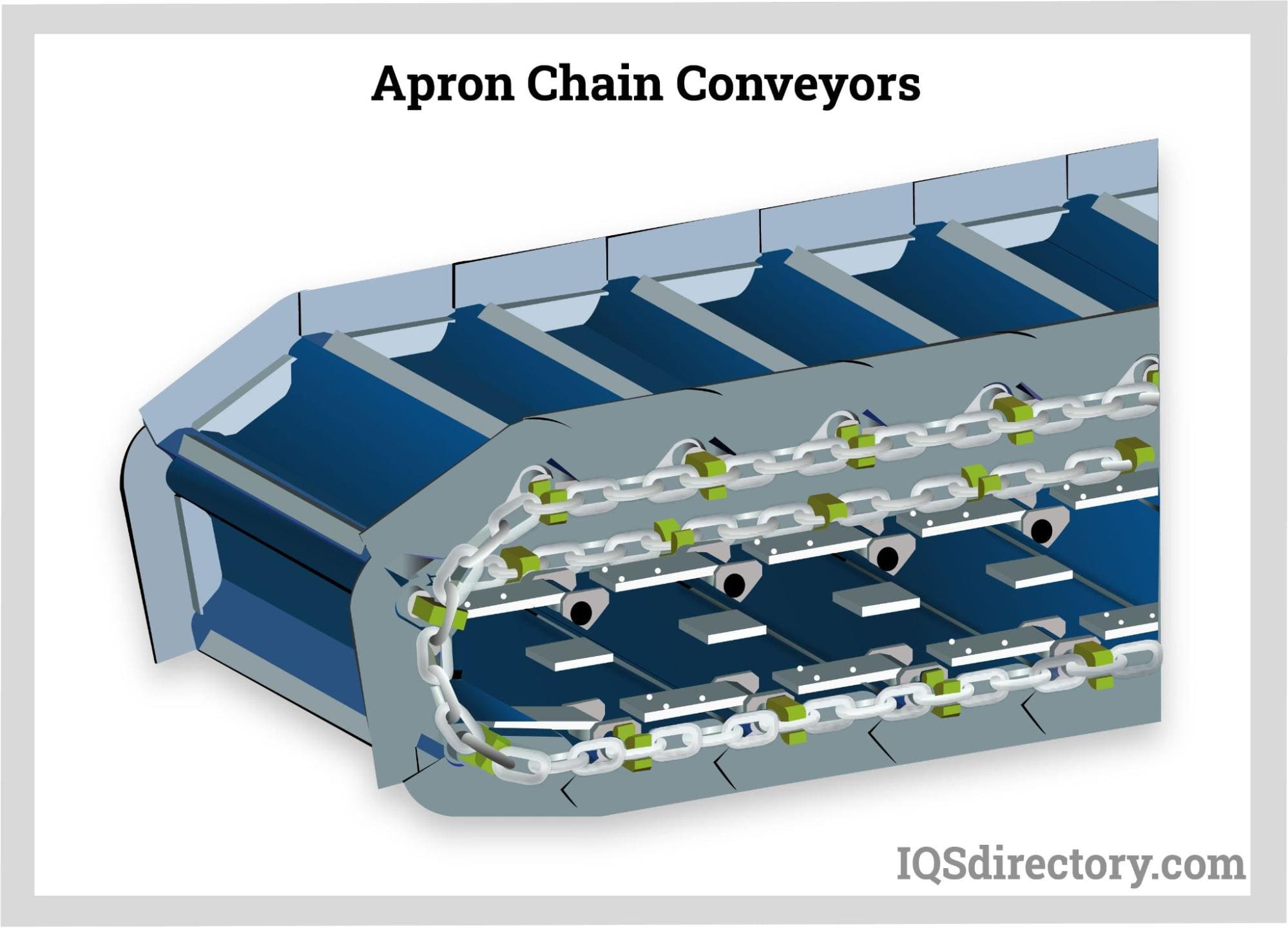

Apron Conveyors

A continuous carrying surface that creates a leakproof bed appropriate for bulk goods without containers is provided by apron conveyors, which are endless chains with coupled overlapping and interlocking plates.

Plain Chain Conveyors

These do not have any attached auxiliary members and carry loads directly on the chain links. The chains move along rails, and their top surfaces protrude enough above the tracks to accommodate a variety of flat objects. These chains are frequently used to transport goods like boxes and cases.

Types of Conveyor Chains

Conveyor chains come in a wide variety of varieties. Examples comprise:

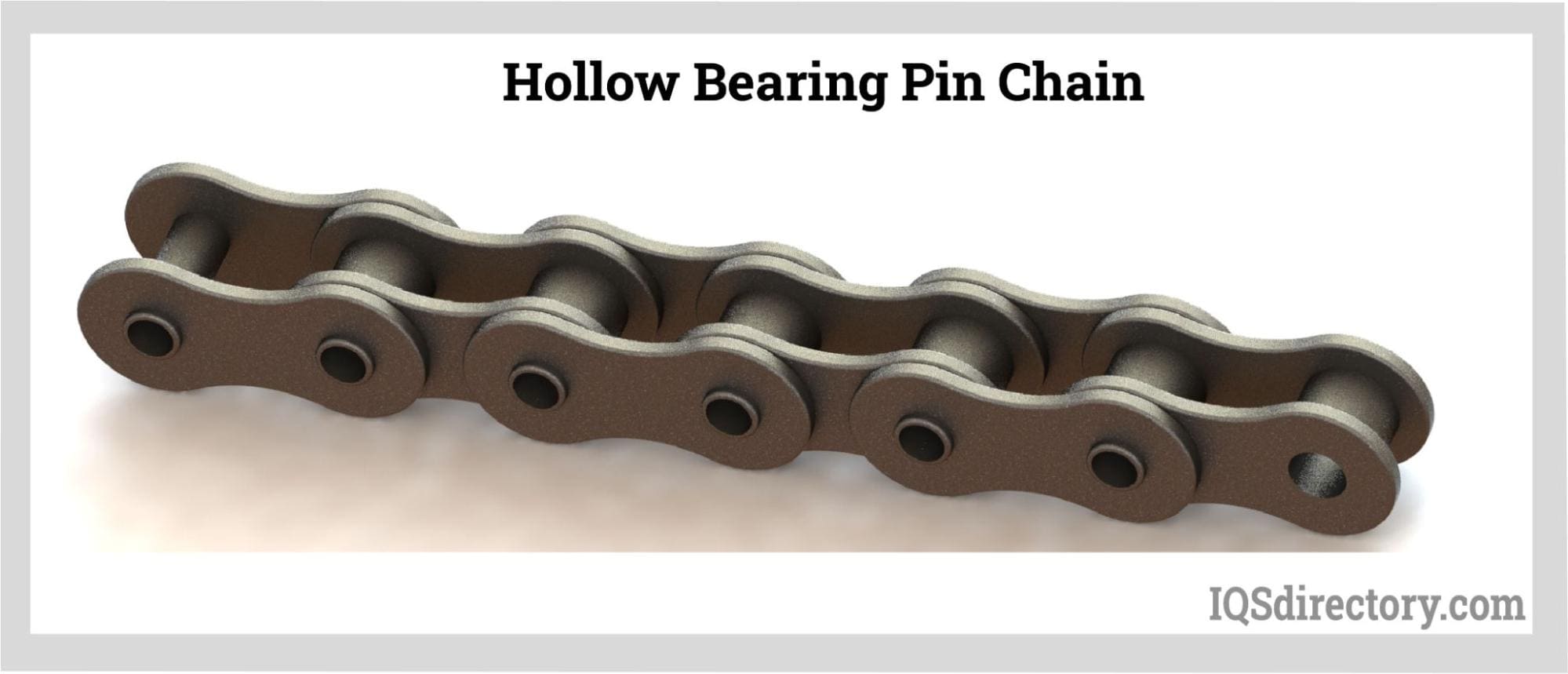

Hollow-Bearing Pin Chains

Attachments can be bolted to a chain's external links and hollow bearing pins. However, bolted attachments should not span the internal link to guarantee the conveyor chain's freedom of articulation.

Deep-Link Chains

Deep side plates on deep-link chains enable continuous carrying above the roller's edge. Conical-shaped bearing pins can be solid or hollow.

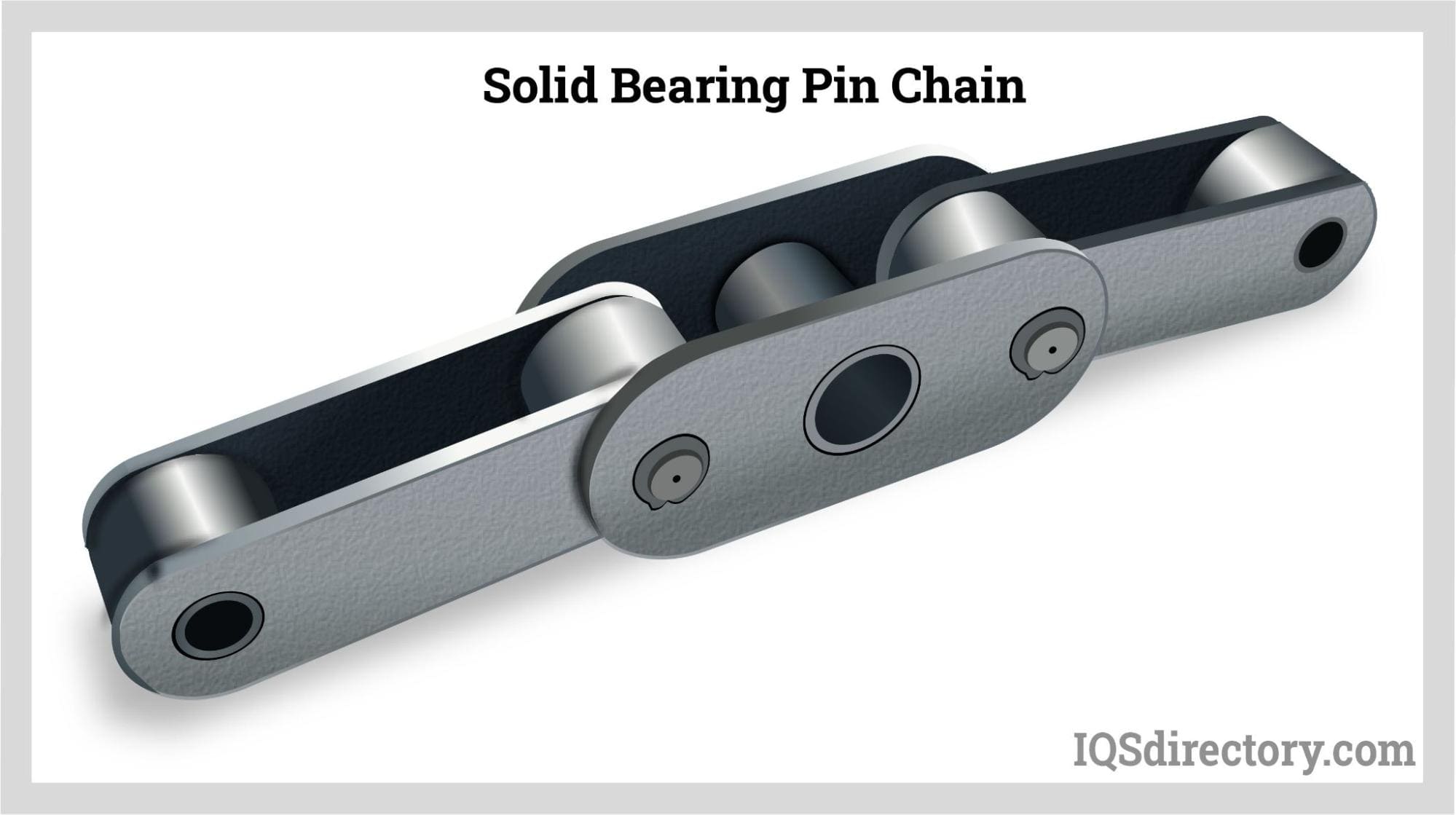

Solid Bearing-Pin Conveyor Chains

The pitch, interior width, and roller diameter of the solid bearing-pin chain are identical to those of the hollow bearing-pin chain. However, the solid-pin chain is made for more demanding conditions.

Chain Conveyor Applications

Coal mining, food processing, sewage treatment, and timber harvesting are examples of applications. Other applications for conveyor chains include sorting, handling, and material conveyors, as well as agricultural, bakery, harvesting, and textile machinery.

Heavy unit loads like pallets, grid boxes, and industrial containers are typically transported using chain conveyors. These conveyors can be set up with a single chain strand or two. When a load is placed on chains, friction causes the load to move forward. In general, chain conveyors require relatively little user maintenance and are simple to build.

Advantages of Chain Conveyors

- Due to the space between individual branches and the large load capacity, it is possible to transport goods that are very wide or very long up to the level of the upper conveyor branch.

- Conveyors are quickly assembled and delivered; the regular version takes up to 14 days to arrive.

- Conveyors are "made-to-measure" or produced under customer specifications.

- An optional number of branches depending on the type of material being transported, the ability to replace individual chain links rather than the entire chain, and the ability to perform special technological or manufacturing operations directly on the conveyor (for example, blowing, degreasing, and draining the oil into the tub underneath the conveyor) are all advantages of chain conveyors.

- The conveyor's skeleton comprises modular system profiles that may be easily connected to other profiles or technologies, giving the conveyor the potential for future modification.

Disadvantages of Chain Conveyors

- 30% of the total power is consumed at no load, which is significant.

- It is not appropriate for long-distance travel.

- Accidents involving chains falling and jumping are frequent.

- It uses a lot of steel—high price.

Choosing the Right Chain Conveyors Manufacturer

To make sure you have the most positive outcome when purchasing Chain Conveyors from a Chain Conveyors Supplier, it is important to compare at least 5 Companies using our Chain Conveyors directory. Each Chain Conveyor Manufacturer has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each Chain Conveyors company website using our patented website previewer to get an idea of what each company specializes in, and then use our simple RFQ form to contact multiple Chain Conveyors businesses with the same quote.

Conveyor Belting

Conveyor Belting Conveyor Systems

Conveyor Systems Conveyors

Conveyors Hosereels

Hosereels Industrial Lubricants

Industrial Lubricants Lubricators

Lubricators Screw Conveyors

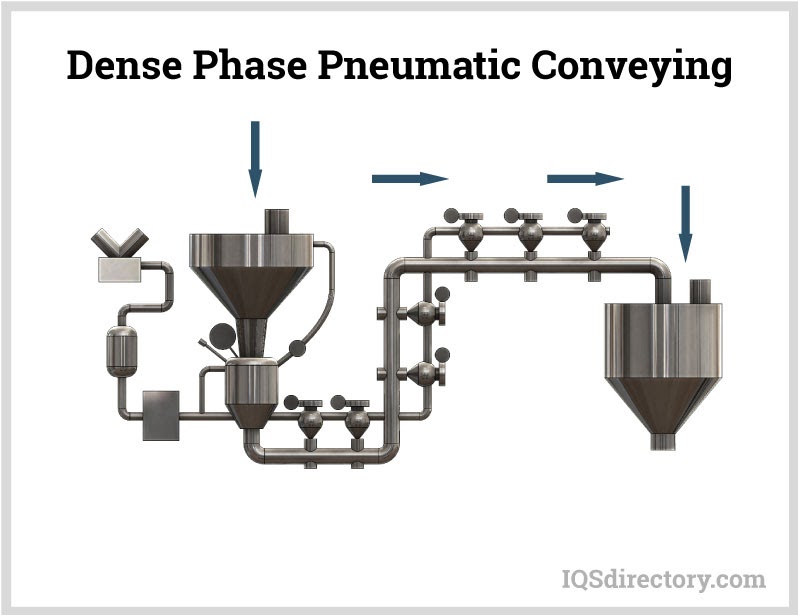

Screw Conveyors Pneumatic Conveyors

Pneumatic Conveyors AGV

AGV Air Pollution Control

Air Pollution Control Assembly Machinery

Assembly Machinery Blowers

Blowers Cranes

Cranes Deburring Machinery

Deburring Machinery Dust Collectors

Dust Collectors Heaters

Heaters Hose Reels

Hose Reels Mezzanines

Mezzanines Modular Buildings

Modular Buildings Storage Racks

Storage Racks Ultrasonic Cleaners

Ultrasonic Cleaners Work Benches

Work Benches