Flexible conveyors are a type of material handling equipment that allows for easy and efficient transportation of goods from one location to another. They are designed to be adaptable and versatile, able to accommodate a wide range of materials and environments. Flexible conveyors are often used in manufacturing and distribution facilities to improve productivity and reduce labor costs. Read More…

VAC-U-MAX is a premier manufacturer of quality conveyors among other similar products and services. VAC-U-MAX produces its equipment to handle small parts and heavy metal powders.

mk North America, Inc. offers the widest variety of conveyors in the industry. Our vast product line features a variety of aluminum frame and stainless-steel conveyors that are built to last. At mk we believe in offering not only a better product, but also a better solution – which is why we will work with you to ensure your unique application is matched with the best possible conveyor...

At Slate River Systems Inc, we take pride in our expertise as innovators in the field of conveyor systems. With years of collective experience, our team is committed to delivering cutting-edge solutions tailored to meet the diverse needs of our clients. Our conveyor systems are engineered to optimize efficiency and streamline material handling processes across various industries.

Redline Systems, Inc. is a leading provider of innovative conveyor solutions. They offer various conveyor types, including portable belt conveyors, incline conveyors, horizontal conveyors, stainless conveyors, and more. Experience the difference with Redline Systems, where innovation meets reliability in conveyor technology.

Impact Automation stands as a prominent force in the field of automation, specializing in the design and implementation of advanced conveying systems tailored for diverse manufacturing processes. With a focus on efficiency, precision, and adaptability, we offer a comprehensive product range that includes sorter feed systems, sorter solutions, traditional conveyors, and plastic belt conveyors.

Spiroflow offers a complete range of mechanical conveying solutions in the industry. The staff at Spiroflow can recommend the best method to meet your conveying needs.

Vecoplan leads the charge with cutting-edge technologies that revolutionize waste and recycling. From versatile shredders and granulators to efficient conveying and sorting systems, Vecoplan offers a wide array of solutions for handling wood, paper, plastics, textiles, and more. Our tailored equipment sets new industry standards, meeting the demands of even the most challenging applications.

More Flexible Conveyor Manufacturers

Components of Flexible Conveyors

The components of flexible conveyors are similar across all variations. They include the conveyor belt, drive unit, supporting structure, and control system. The conveyor belt is the heart of the flexible conveyor, and its function is to transport materials. The drive unit powers the conveyor belt, while the supporting structure provides stability and support. Finally, the control system regulates the speed and direction of the conveyor.

Variations of Flexible Conveyors

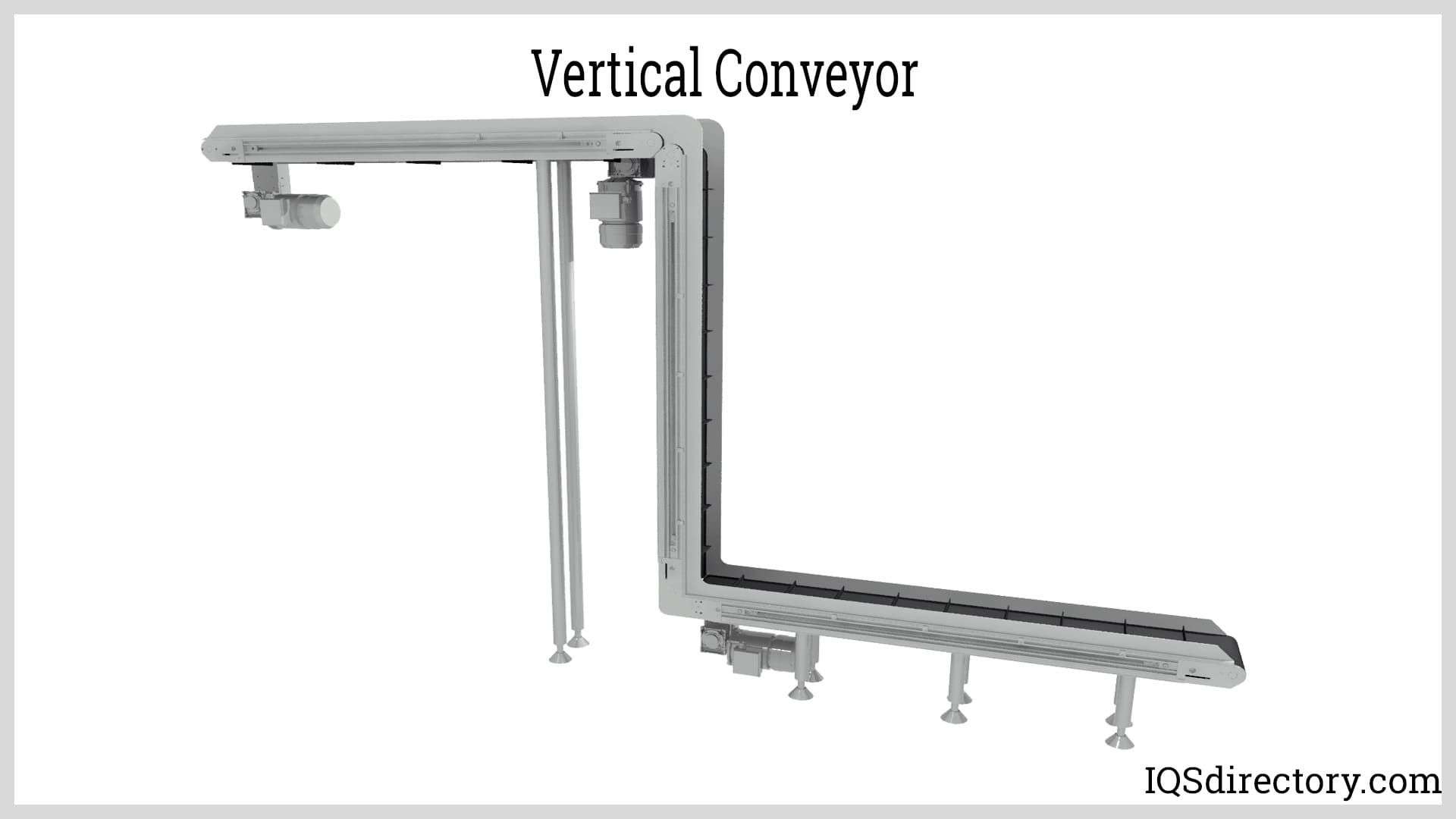

There are several variations in the design of flexible conveyors. One such variation is the telescopic conveyor, which can be extended and contracted to adjust to different lengths. This type of conveyor is ideal for loading and unloading trucks, as it can be adjusted to fit the length of the truck bed. Another variation is the curved conveyor, which is designed to transport materials around corners. This type of conveyor is often used in facilities with limited space.

Considerations Regarding Flexible Conveyors

While flexible conveyors offer many benefits, there are some considerations to keep in mind. For example, flexible conveyors can be difficult to clean, which can lead to contamination and reduced product quality. Additionally, they can be prone to jams and breakdowns, which can lead to production downtime and increased costs.

Benefits of Flexible Conveyors

Despite these considerations, flexible conveyors offer numerous benefits, such as:

Highly Adaptable

One of the primary benefits of flexible conveyors is their high adaptability. They can be easily adjusted to fit a wide range of spaces and applications, making them a versatile solution for transporting materials. For example, telescopic conveyors can be extended or retracted to fit the length of a truck bed, while other conveyors can be curved or angled to fit around obstacles or to navigate around corners.

Efficiency

Flexible conveyors are also highly efficient, allowing materials to be transported quickly and easily from one location to another. They can be easily integrated into existing systems, reducing the need for manual labor and increasing productivity. Flexible conveyors are particularly useful in applications where speed and efficiency are critical, such as in manufacturing facilities, distribution centers, and e-commerce fulfillment centers.

Ease of Use

Flexible conveyors are designed to be user-friendly, with simple controls and easy-to-understand instructions. They can be easily operated by trained personnel, reducing the need for specialized skills or training. This makes them a practical solution for facilities with a high turnover of personnel or for applications where workers need to be quickly trained to operate the conveyor system.

Cost-Effective

Flexible conveyors are also a cost-effective solution for transporting materials. They are generally less expensive than other types of conveyor systems, and they require minimal maintenance and repair. They can also be easily reconfigured or relocated, reducing the need for expensive modifications or new equipment.

Increased Safety

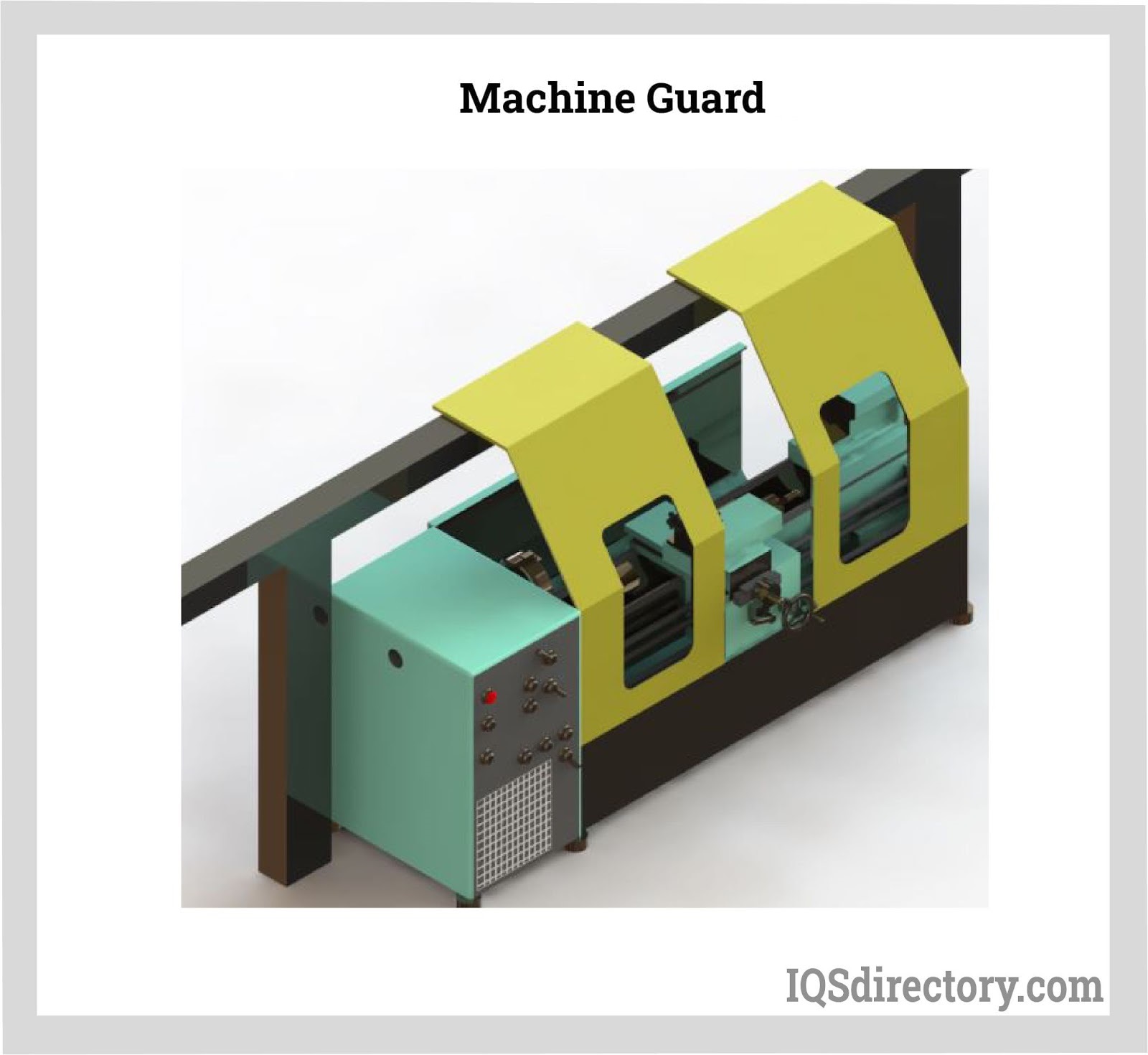

Flexible conveyors are designed with safety in mind. They are equipped with safety features such as emergency stop buttons, guards, and safety sensors, which help to prevent accidents and injuries. They are also designed to minimize the risk of material damage, reducing the need for costly repairs or replacements.

Improved Ergonomics

Flexible conveyors can also improve ergonomics in the workplace. They are designed to minimize physical strain on workers, reducing the risk of workplace injuries and fatigue. For example, telescopic conveyors can be adjusted to the height of the worker, reducing the need for bending or reaching. This can help to improve worker productivity and reduce the risk of injury.

Environmental Benefits

Flexible conveyors can also provide environmental benefits. They can be used to transport materials more efficiently, reducing the need for multiple trips and minimizing energy usage. This can help to reduce carbon emissions and other environmental impacts associated with transportation.

Applications of Flexible Conveyors

Due to these benefits, flexible conveyors have numerous applications across a wide range of industries, including:

Manufacturing Facilities

Flexible conveyors are commonly used in manufacturing facilities to transport materials between different stages of the production process. They are particularly useful for applications where materials need to be moved quickly and efficiently. In manufacturing facilities, flexible conveyors can be used for assembly line production, material handling, and quality control. They are also useful for transporting materials to and from storage areas and shipping docks.

Distribution Centers

Distribution centers often rely on flexible conveyors to load and unload trucks quickly and efficiently. Telescopic conveyors are particularly useful in this application, as they can be adjusted to fit the length of the truck bed. This type of conveyor is also useful for transferring materials between different areas of the distribution center, such as from storage to the loading dock.

Warehouses

In warehouses, flexible conveyors are commonly used to transport goods from one location to another. This can include moving goods from storage areas to shipping docks, as well as moving materials between different areas of the warehouse. Flexible conveyors are particularly useful in warehouses that handle a large volume of goods or have limited space.

Food and Beverage Industry

Flexible conveyors are commonly used in the food and beverage industry, particularly for handling perishable goods. They are designed to be easy to clean and sanitize, making them ideal for applications where hygiene is critical. Flexible conveyors can be used for a wide range of applications in the food and beverage industry, including transporting raw materials, packaging products, and finished goods.

E-Commerce Fulfillment Centers

Flexible conveyors are essential in e-commerce fulfillment centers, where efficiency and speed are critical. They are used to transport goods from storage areas to the picking and packing areas, as well as to move products from the packing area to the shipping dock. Flexible conveyors can be adjusted to fit a wide range of spaces and are ideal for facilities that handle a high volume of goods.

Automotive Industry

Flexible conveyors are widely used in the automotive industry, particularly for assembly line production. They are used to transport components and materials to different stages of the assembly process, as well as to move finished vehicles from the production line to the shipping dock. Flexible conveyors are particularly useful in the automotive industry because they can be easily adapted to accommodate different types of vehicles and components.

Pharmaceutical Industry

Flexible conveyors are also used in the pharmaceutical industry for handling and transporting sensitive materials. They are designed to be easy to clean and sanitize, and are often used for applications such as moving raw materials to the production line, transporting finished products to the packaging area, and moving products through quality control checkpoints.

Choosing the Correct Flexible Conveyor Manufacturer

To ensure you have the most productive outcome when purchasing a flexible conveyor from a flexible conveyor manufacturer, it is important to compare several companies using our directory of flexible conveyor manufacturers. Each flexible conveyor manufacturer has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the manufacturer for more information or to request a quote. Review each flexible conveyor business website using our proprietary website previewer to quickly learn what each company specializes in. then, use our simple RFQ form to contact multiple flexible conveyor businesses with the same form.

Conveyor Belting

Conveyor Belting Conveyor Systems

Conveyor Systems Conveyors

Conveyors Hosereels

Hosereels Industrial Lubricants

Industrial Lubricants Lubricators

Lubricators Screw Conveyors

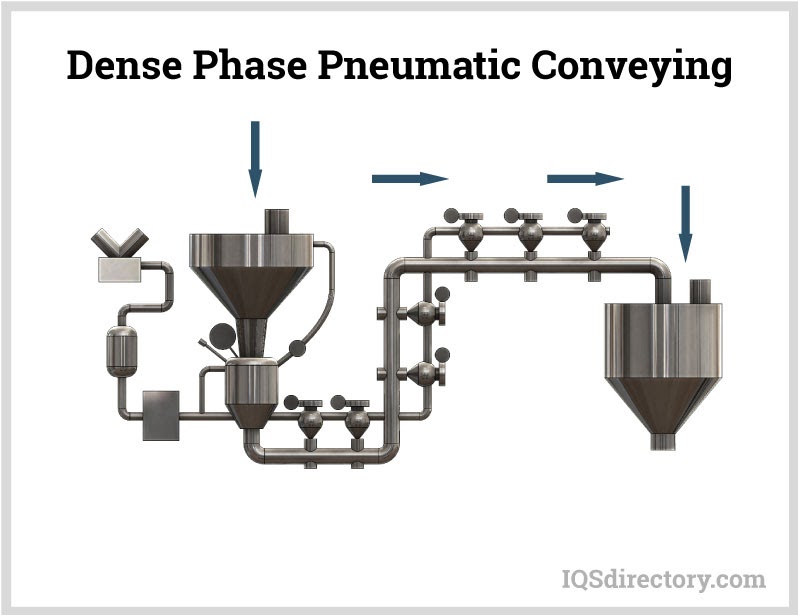

Screw Conveyors Pneumatic Conveyors

Pneumatic Conveyors AGV

AGV Air Pollution Control

Air Pollution Control Assembly Machinery

Assembly Machinery Blowers

Blowers Cranes

Cranes Deburring Machinery

Deburring Machinery Dust Collectors

Dust Collectors Heaters

Heaters Hose Reels

Hose Reels Mezzanines

Mezzanines Modular Buildings

Modular Buildings Storage Racks

Storage Racks Ultrasonic Cleaners

Ultrasonic Cleaners Work Benches

Work Benches