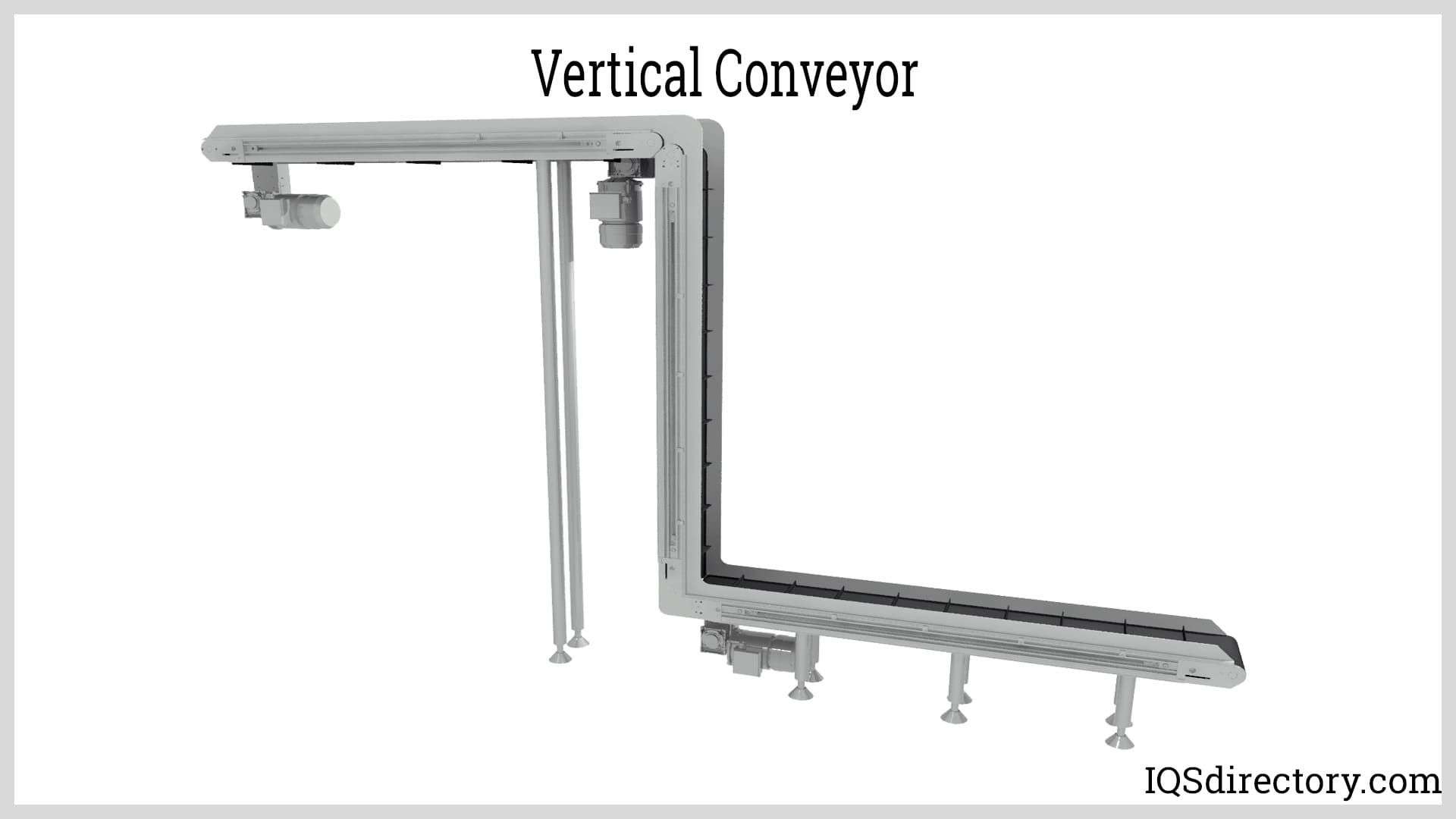

Vertical conveyors are essential equipment used in various industries to transport materials and products vertically and horizontally. Read More…

VAC-U-MAX is a premier manufacturer of quality conveyors among other similar products and services. VAC-U-MAX produces its equipment to handle small parts and heavy metal powders.

mk North America, Inc. offers the widest variety of conveyors in the industry. Our vast product line features a variety of aluminum frame and stainless-steel conveyors that are built to last. At mk we believe in offering not only a better product, but also a better solution – which is why we will work with you to ensure your unique application is matched with the best possible conveyor...

At RMH Systems, we specialize in crafting innovative conveyor systems that streamline operations and maximize efficiency for a wide range of industries. Our expertly designed conveyor solutions are tailored to meet the unique needs of each client, ensuring seamless integration into existing processes.

At Slate River Systems Inc, we take pride in our expertise as innovators in the field of conveyor systems. With years of collective experience, our team is committed to delivering cutting-edge solutions tailored to meet the diverse needs of our clients. Our conveyor systems are engineered to optimize efficiency and streamline material handling processes across various industries.

Many types, sizes, makes & models of shelving available online at SJF.com. We buy & sell warehouse equipment with the nation's largest inventory of new and used material handling equipment: over 20 acres! Explore our website & find dealer direct savings on shelving & more types of material handling equipment.

Spiroflow offers a complete range of mechanical conveying solutions in the industry. The staff at Spiroflow can recommend the best method to meet your conveying needs.

If you are in need of conveyors that are built to last, you can count on us to be your number one provider. We manufacture conveyors that guarantee efficiency and stability. Our teams offer fast turnaround on all orders and if an issue ever arises then we will work with you to quickly repair your systems. Give us a call today or visit our website to learn more information!

More Vertical Conveyor Manufacturers

Components and Functioning of Vertical Conveyors

Vertical conveyors are composed of various components, including a drive unit, conveyor belt, pulleys, supports, and safety features. The drive unit is responsible for providing power to move the conveyor belt. The conveyor belt is the surface that supports and transports the material being conveyed. The pulleys guide and tension the belt. Supports hold the conveyor in place and prevent it from sagging or collapsing under the weight of the load. Safety features, such as emergency stops and warning alarms, ensure safe operation.

Types of Vertical Conveyors

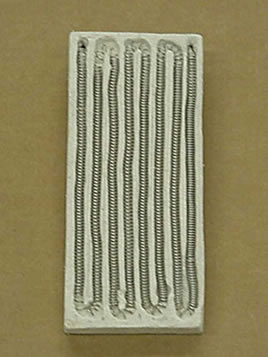

There are different types of vertical conveyors based on their design, such as continuous lift conveyors, reciprocating lift conveyors, and spiral conveyors. Continuous lift conveyors are suitable for transporting heavy loads and materials over long distances. Reciprocating lift conveyors are used for lifting products between two or more levels, while spiral conveyors are ideal for transporting materials vertically or horizontally within a confined space.

Considerations Regarding Vertical Conveyors

A major consideration regarding vertical conveyors is that they may produce noise pollution and vibration, which can affect a work environment. Maintenance requirements are also a factor that needs to be considered, as worn-out components or defective equipment can cause production downtime. Vertical conveyors can also be expensive to install, especially for large-scale systems. Additionally, there are limitations on the size and weight of items transported, which can restrict their use in some industries.

Benefits of Vertical Conveyors

On the other hand, vertical conveyors offer numerous benefits, making them a popular choice in different industries. One of the most significant benefits is the reduction of floor space requirements. Unlike traditional conveyors, vertical conveyors transport items vertically, enabling the utilization of unused overhead space. Vertical conveyors can also transport items at high speeds and over long distances, increasing efficiency and productivity. Additionally, vertical conveyors reduce manual labor and ensure better control over product quality and safety. Moreover, vertical conveyors can be designed to integrate with automated systems, making them highly versatile and adaptable. This is especially true for the manufacturing industry, where vertical conveyors can streamline production processes and increase output.

Applications of Vertical Conveyors

As a result of these benefits, vertical conveyors have various applications in different industries, including:

Warehousing and Distribution Centers

Vertical conveyors are widely used in warehousing and distribution centers to transport products and materials between different levels. They help maximize the use of available space, as the vertical conveyor's compact design saves floor space. They can transport a wide range of products, including boxes, pallets, and cartons, and can handle heavy loads.

Manufacturing and Assembly Lines

Vertical conveyors play a crucial role in the manufacturing and assembly lines by transporting components and finished products between different stages of production. They help streamline production processes, minimize manual labor, and ensure better quality control. Vertical conveyors can transport a wide range of products, including raw materials, semi-finished products, and finished products.

Mining and Construction Sites

Vertical conveyors are commonly used in mining and construction sites to transport heavy loads and materials up and down steep inclines. They help minimize the manual labor required for transporting materials, which can be difficult and hazardous. Vertical conveyors can handle heavy loads, including rocks, gravel, and ores.

Agriculture and Farming Operations

Vertical conveyors are used in agriculture and farming operations to sort and package fruits, vegetables, and other produce. They help streamline production processes, reduce manual labor, and improve productivity. Vertical conveyors can transport a wide range of products, including crates, boxes, and bags.

Airports and Logistics Hubs

Vertical conveyors are widely used in airports and logistics hubs to transport baggage and cargo between different levels. They help minimize manual labor and ensure efficient and timely transport of baggage and cargo. Vertical conveyors can handle a wide range of products, including suitcases, boxes, and pallets.

Food and Beverage Industry

Vertical conveyors are used in the food and beverage industry to transport materials, such as grains and sugar, to and from storage areas. They help minimize manual labor, ensure better quality control, and reduce the risk of contamination. Vertical conveyors can handle a wide range of products, including bags, boxes, and containers.

Pharmaceutical and Healthcare Industries

Vertical conveyors are used in the pharmaceutical and healthcare industries to transport medicines and equipment between different levels. They help minimize manual labor, ensure better quality control, and reduce the risk of contamination. Vertical conveyors can handle a wide range of products, including boxes, vials, and containers.

Choosing the Correct Vertical Conveyor Manufacturer

To ensure you have the most productive outcome when purchasing a vertical conveyor from a vertical conveyor manufacturer, it is important to compare several companies using our directory of vertical conveyor manufacturers. Each vertical conveyor manufacturer has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the manufacturer for more information or to request a quote. Review each vertical conveyor business website using our patented website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple vertical conveyor companies with the same form.

Conveyor Belting

Conveyor Belting Conveyor Systems

Conveyor Systems Conveyors

Conveyors Hosereels

Hosereels Industrial Lubricants

Industrial Lubricants Lubricators

Lubricators Screw Conveyors

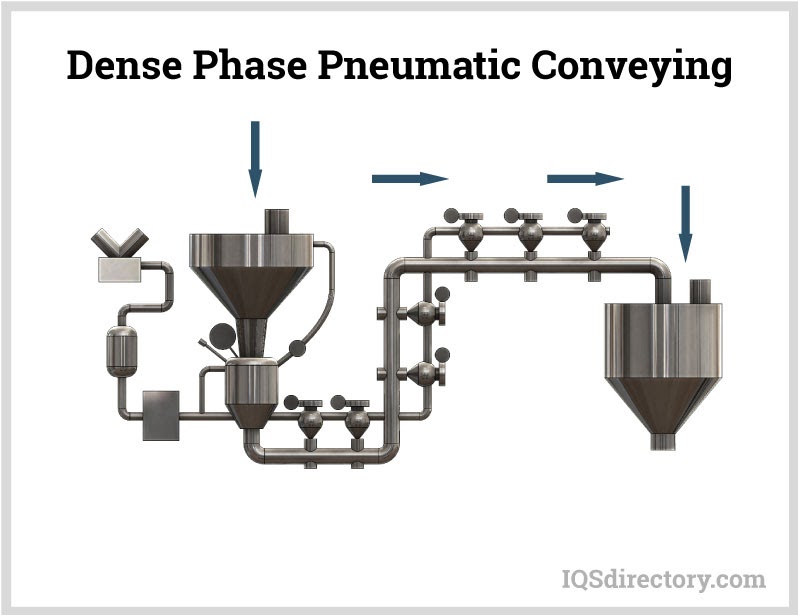

Screw Conveyors Pneumatic Conveyors

Pneumatic Conveyors AGV

AGV Air Pollution Control

Air Pollution Control Assembly Machinery

Assembly Machinery Blowers

Blowers Cranes

Cranes Deburring Machinery

Deburring Machinery Dust Collectors

Dust Collectors Heaters

Heaters Hose Reels

Hose Reels Mezzanines

Mezzanines Modular Buildings

Modular Buildings Storage Racks

Storage Racks Ultrasonic Cleaners

Ultrasonic Cleaners Work Benches

Work Benches