Roller conveyors are a sequence of rollers held in a frame where items can be moved manually, by power, or by gravity. There are a number of ways roller conveyors can be utilized and adjusted for different applications, including moving cardboard boxes, boxes, pallets, crates, plastic totes, polybags, trays, and slave boards. Read More…

VAC-U-MAX is a premier manufacturer of quality conveyors among other similar products and services. VAC-U-MAX produces its equipment to handle small parts and heavy metal powders.

mk North America, Inc. offers the widest variety of conveyors in the industry. Our vast product line features a variety of aluminum frame and stainless-steel conveyors that are built to last. At mk we believe in offering not only a better product, but also a better solution – which is why we will work with you to ensure your unique application is matched with the best possible conveyor...

At Slate River Systems Inc, we take pride in our expertise as innovators in the field of conveyor systems. With years of collective experience, our team is committed to delivering cutting-edge solutions tailored to meet the diverse needs of our clients. Our conveyor systems are engineered to optimize efficiency and streamline material handling processes across various industries.

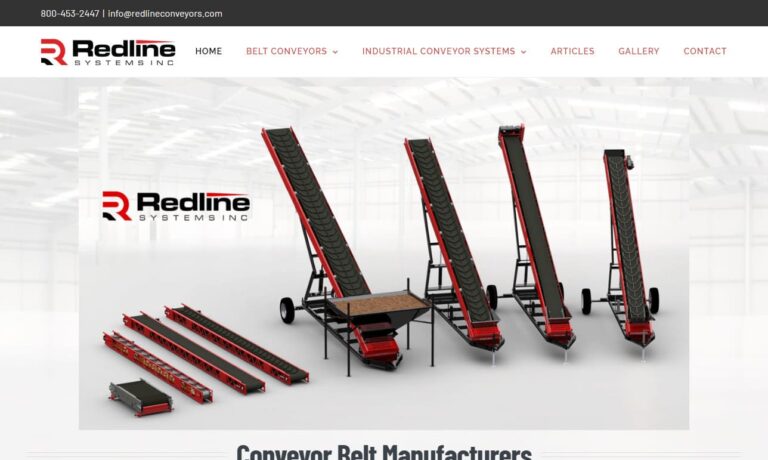

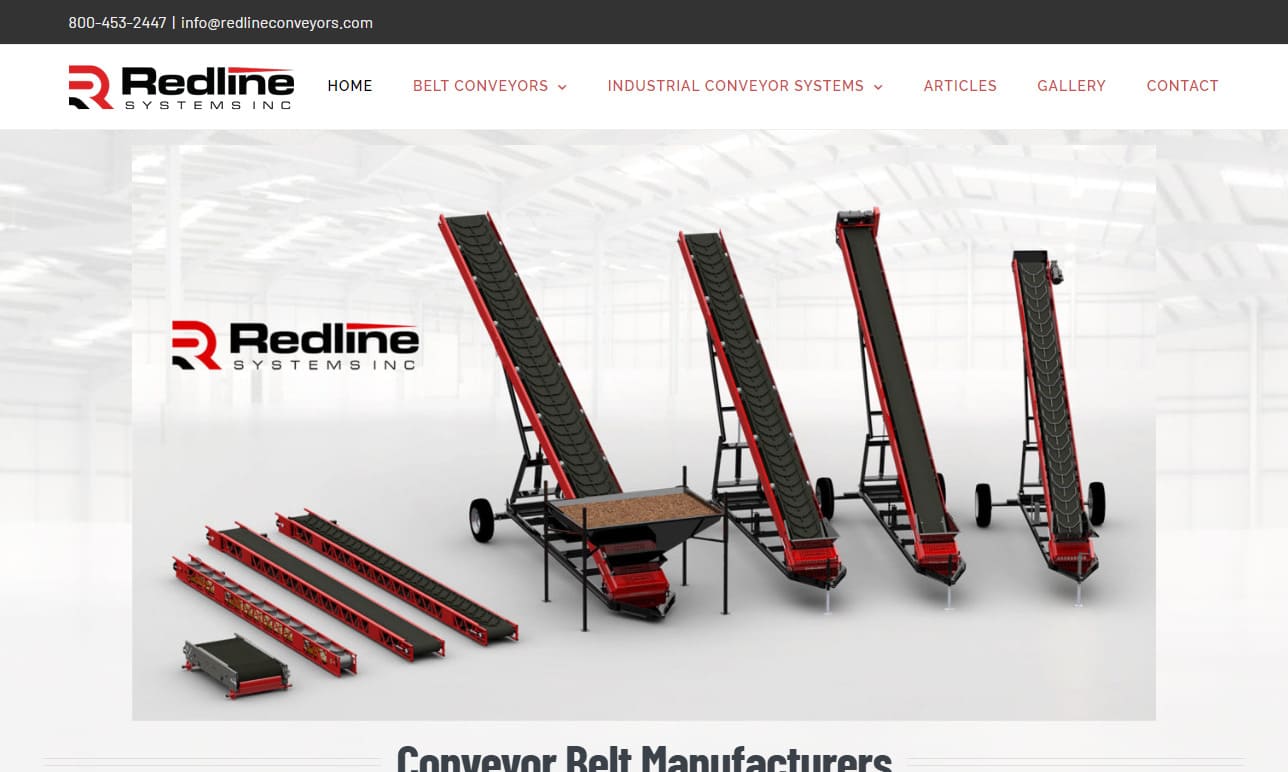

Redline Systems, Inc. is a leading provider of innovative conveyor solutions. They offer various conveyor types, including portable belt conveyors, incline conveyors, horizontal conveyors, stainless conveyors, and more. Experience the difference with Redline Systems, where innovation meets reliability in conveyor technology.

Impact Automation stands as a prominent force in the field of automation, specializing in the design and implementation of advanced conveying systems tailored for diverse manufacturing processes. With a focus on efficiency, precision, and adaptability, we offer a comprehensive product range that includes sorter feed systems, sorter solutions, traditional conveyors, and plastic belt conveyors.

Spiroflow offers a complete range of mechanical conveying solutions in the industry. The staff at Spiroflow can recommend the best method to meet your conveying needs.

Vecoplan leads the charge with cutting-edge technologies that revolutionize waste and recycling. From versatile shredders and granulators to efficient conveying and sorting systems, Vecoplan offers a wide array of solutions for handling wood, paper, plastics, textiles, and more. Our tailored equipment sets new industry standards, meeting the demands of even the most challenging applications.

More Roller Conveyor Manufacturers

What is a Roller Conveyor?

Roller conveyors are a sequence of rollers held in a frame where items can be moved manually, by power, or by gravity. There are a number of ways roller conveyors can be utilized and adjusted for different applications, including moving cardboard boxes, boxes, pallets, crates, plastic totes, polybags, trays, and slave boards. A roller conveyor system may be constructed to work with a number of ancillary devices like bends, turntables, and gates.

How a Roller Conveyor is Made

There are a number of parts that are generic on all types of roller conveyors. These are discussed below.

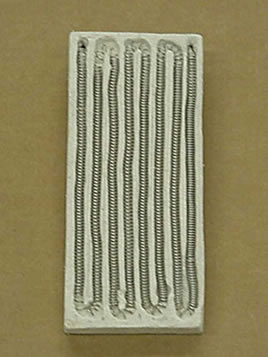

Rollers for Roller Conveyors

These are cylinders made of metal fixed into the assembly combined with a metal axis and two bearings. This part is different depending on the type of conveyors. It may be substituted with chains or belts.

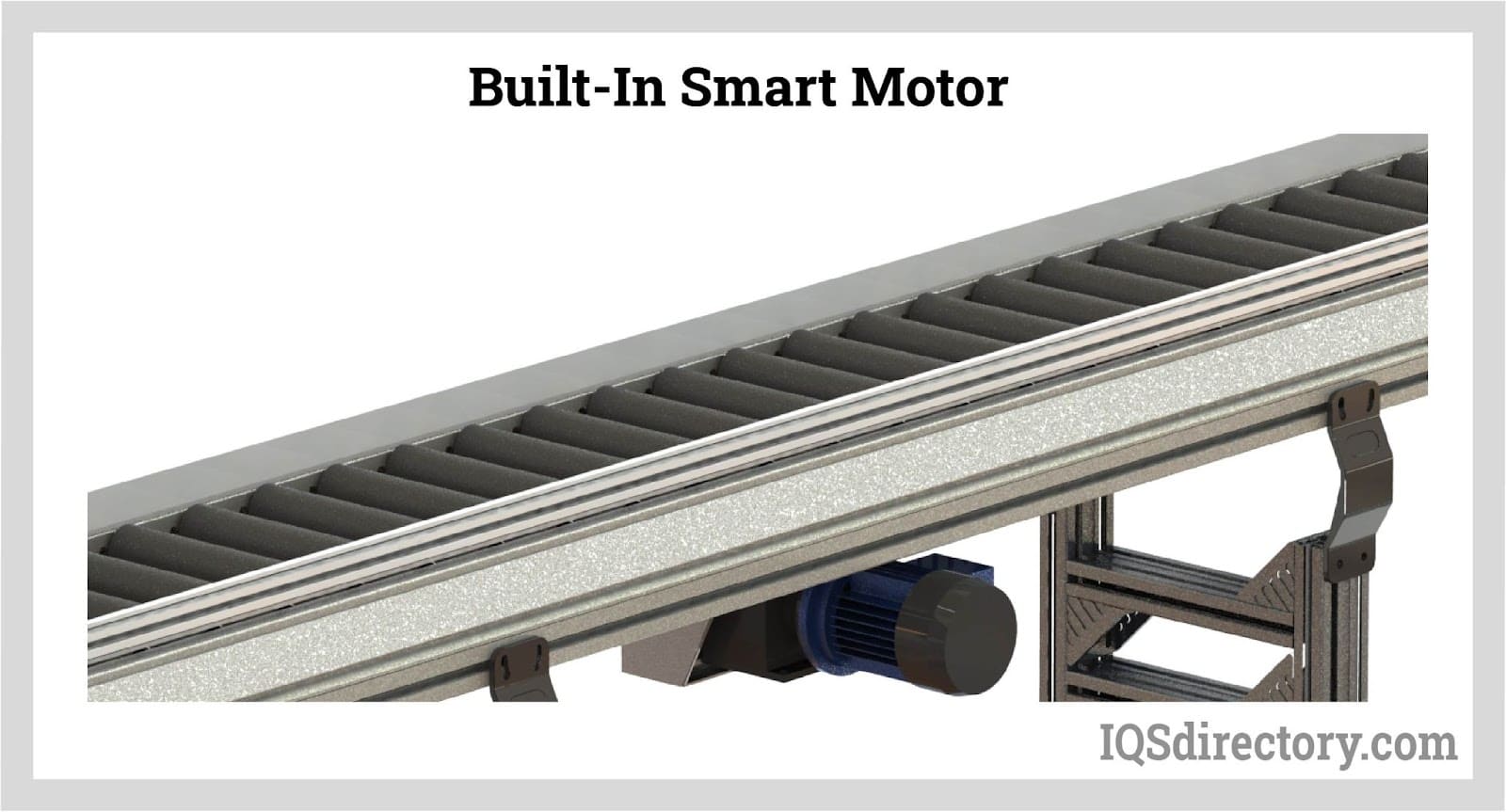

Motor for Roller Conveyors

AC induction motors are used for roller conveyors because they operate continuously in one direction. In cases where the motor must operate perpetually in one direction at synchronous speeds, synchronous motors are used.

Where controlling speed is important or it changes frequently there are motors which offer wide speed control range and constant torque. For conveyors that need higher accuracy positioning, stepper motors and servo motors are suitable.

Structure and Legs for Roller Conveyors

They support rollers. They are constructed of steel because it is strong and durable in handling heavy loads.

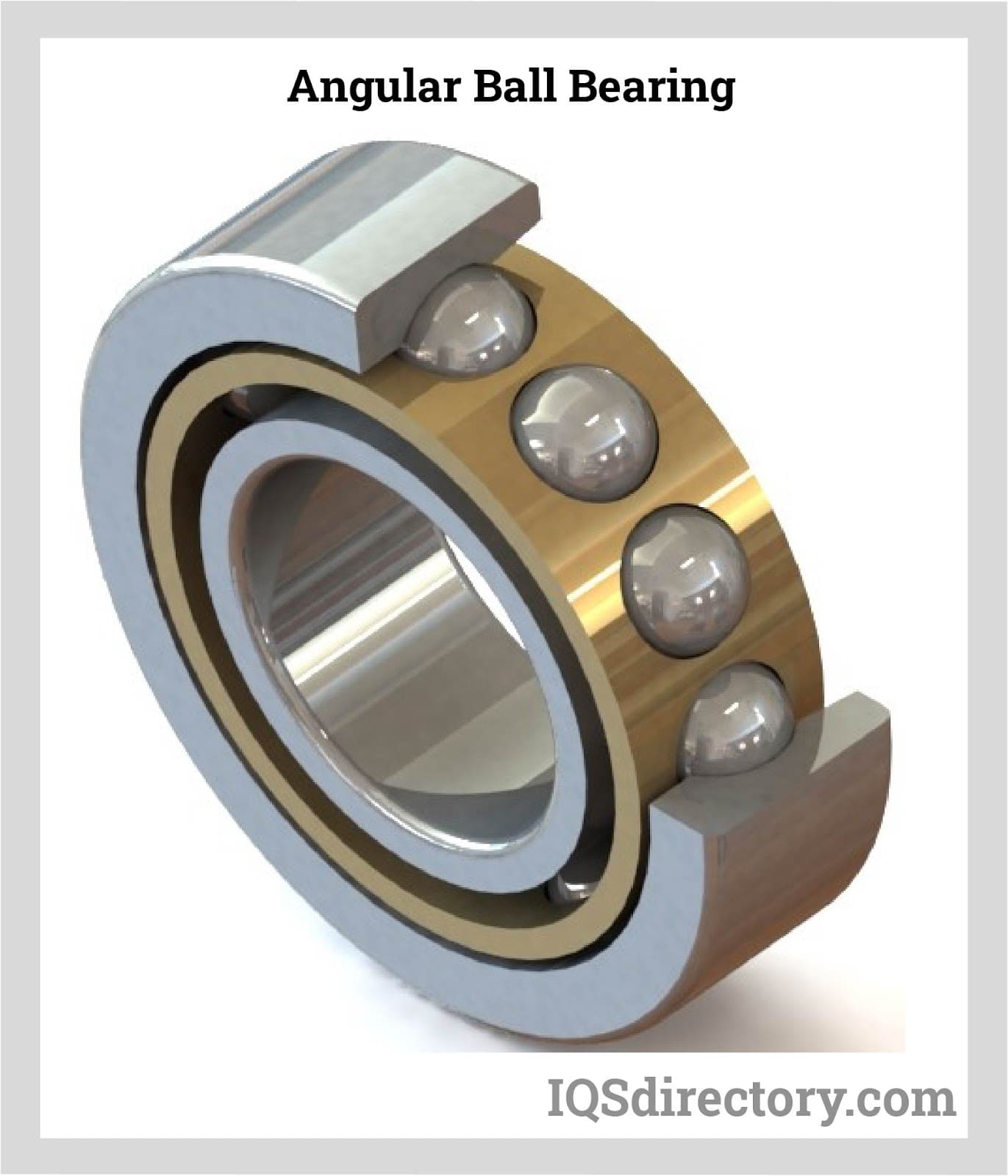

Non Precision Bearings for Roller Conveyors

There are two main types of ball bearings used in roller conveyors.

Angular Contact Ball Bearings

Angular contact ball bearings are constructed to be placed in proximity to each other in the direction of the bearing axis. Thus combined loads are handled at the same time handling axial and radial loads.

Pillow Block Bearing

These are pedestals which support spinning shafts using various accessories and compatible bearings. Pillow block bearings are commonly applied in the most arduous food and beverage industries. Cast iron or cast steel is used to construct a majority of their housing.

Sprockets for Roller Conveyors

They are applied with chains or rollers, they feature toothed gears or profiled wheels to provide rotational motion.

Types of Roller Conveyors

The different types of roller conveyors include:

Gravity Roller Conveyor

They let items move on rollers applying the force of gravity in moving the load. Gravity conveyors are a very simple and cost effective type of product handling systems. They function by permitting the material to roll on the upper surface.

Belt Driven Roller Conveyor

They are a sequence of rollers supported by a structure appropriate for unit handling items which are moved by a belt. They are best for moving a huge number of light and heavy items of irregular or regular shape. The system is mainly silent running, even at high speeds.

Chain Driven Roller Conveyor

Chain driven roller conveyors are used to move pallets and other unit items. The rollers are moved by a chain and offer the power required to move pallets. This heavy duty roller conveyor may be combined with transfers for angular transfer in roller conveyor systems.

Line Shaft Roller Conveyor

They are powered by a shaft under the rollers. These conveyors are perfect for light usage, reaching 50 kg like tote boxes and cardboard boxes. On the shaft are a number of spools, for each roller there is one spool.

Powered Roller Conveyors

They are 24V conveyors for efficient and precise movement of containers, boxes, or totes. Perfect for zero pressure accumulation. Each zone may be controlled separately. The controlling units are pre-installed in the extrusion, enclosed, and ready to use.

Motor Driven Live Roller (MDLR)

Motor driven live rollers are a quite new conveyor type. They utilize small DC motors to drive transportation rollers. Frequently, the motor is built inside a roller. These small DC motors are spread throughout the conveyor. Each motor is an accumulation zone.

Applications of Roller Conveyors

They are applied in a variety of industries listed below:

- Manufacturing and design

- Food handling

- Mail delivery services

- Baggage handling

- Steelmaking

- Packaging

- Logistics

Choosing the Right Roller Conveyor

When choosing a roller conveyor it is important to consider the following:

Material Characteristics

It is important to pay attention to the height, width, length, and weight since the technical specifications of the system are ultimately dependent on these characteristics.

Production Rate and Accumulation Choice

By determining the rate of production, the required conveyor speed is determined so it meets throughput requirements and reduces downtime.

Conveying Requirements

Details like conveying volume, elevation, and distance are one of the primary factors which influence the choice.

Environmental Conditions

Temperature, sunlight, moisture, and dust at an industrial site demand exceptional belt qualities and steel specifications.

Choosing the Proper Roller Conveyors Supplier

To make sure you have the most positive outcome when purchasing Roller Conveyors from a Roller Conveyors Supplier, it is important to compare at least 4 or 5 Suppliers using our list of Roller Conveyors companies. Each Roller Conveyors Company has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each Roller Conveyors business website using our patented website previewer to get an idea of what each business specializes in, and then use our simple RFQ form to contact multiple Roller Conveyors companies with the same quote.

Conveyor Belting

Conveyor Belting Conveyor Systems

Conveyor Systems Conveyors

Conveyors Hosereels

Hosereels Industrial Lubricants

Industrial Lubricants Lubricators

Lubricators Screw Conveyors

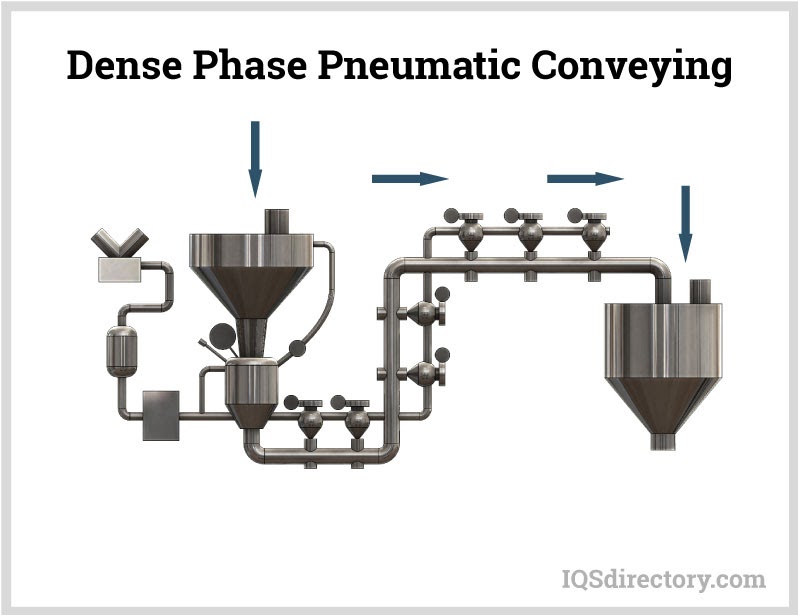

Screw Conveyors Pneumatic Conveyors

Pneumatic Conveyors AGV

AGV Air Pollution Control

Air Pollution Control Assembly Machinery

Assembly Machinery Blowers

Blowers Cranes

Cranes Deburring Machinery

Deburring Machinery Dust Collectors

Dust Collectors Heaters

Heaters Hose Reels

Hose Reels Mezzanines

Mezzanines Modular Buildings

Modular Buildings Storage Racks

Storage Racks Ultrasonic Cleaners

Ultrasonic Cleaners Work Benches

Work Benches