Belt conveyors are devices that transport materials, supplies, and other objects from one place to another within a facility while reducing the time, energy, and costs required. Belt conveyors provide an efficient means for many industries to transport heavy and bulky materials, boxes, and their manufactured items across production floors. Belt conveyors may function independently or as part of a larger system. Read More…

VAC-U-MAX is a premier manufacturer of quality conveyors among other similar products and services. VAC-U-MAX produces its equipment to handle small parts and heavy metal powders.

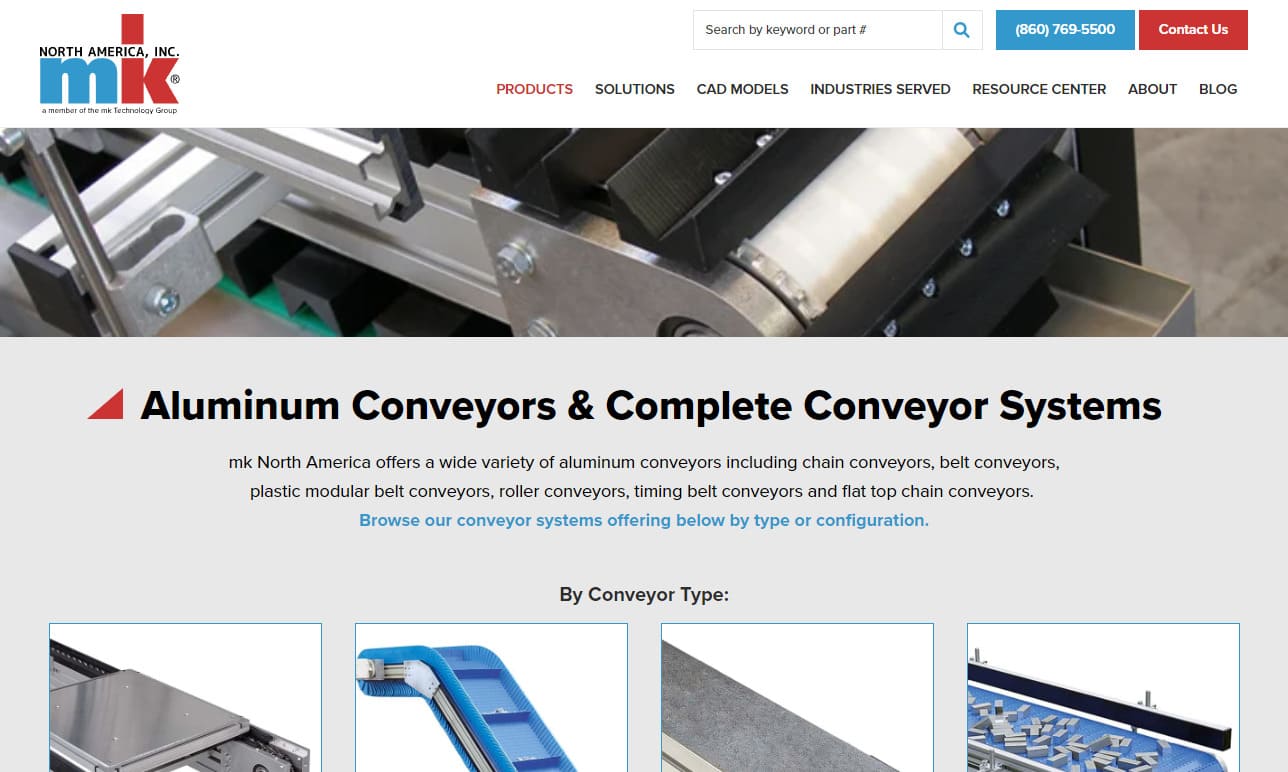

mk North America, Inc. offers the widest variety of conveyors in the industry. Our vast product line features a variety of aluminum frame and stainless-steel conveyors that are built to last. At mk we believe in offering not only a better product, but also a better solution – which is why we will work with you to ensure your unique application is matched with the best possible conveyor...

At Slate River Systems Inc, we take pride in our expertise as innovators in the field of conveyor systems. With years of collective experience, our team is committed to delivering cutting-edge solutions tailored to meet the diverse needs of our clients. Our conveyor systems are engineered to optimize efficiency and streamline material handling processes across various industries.

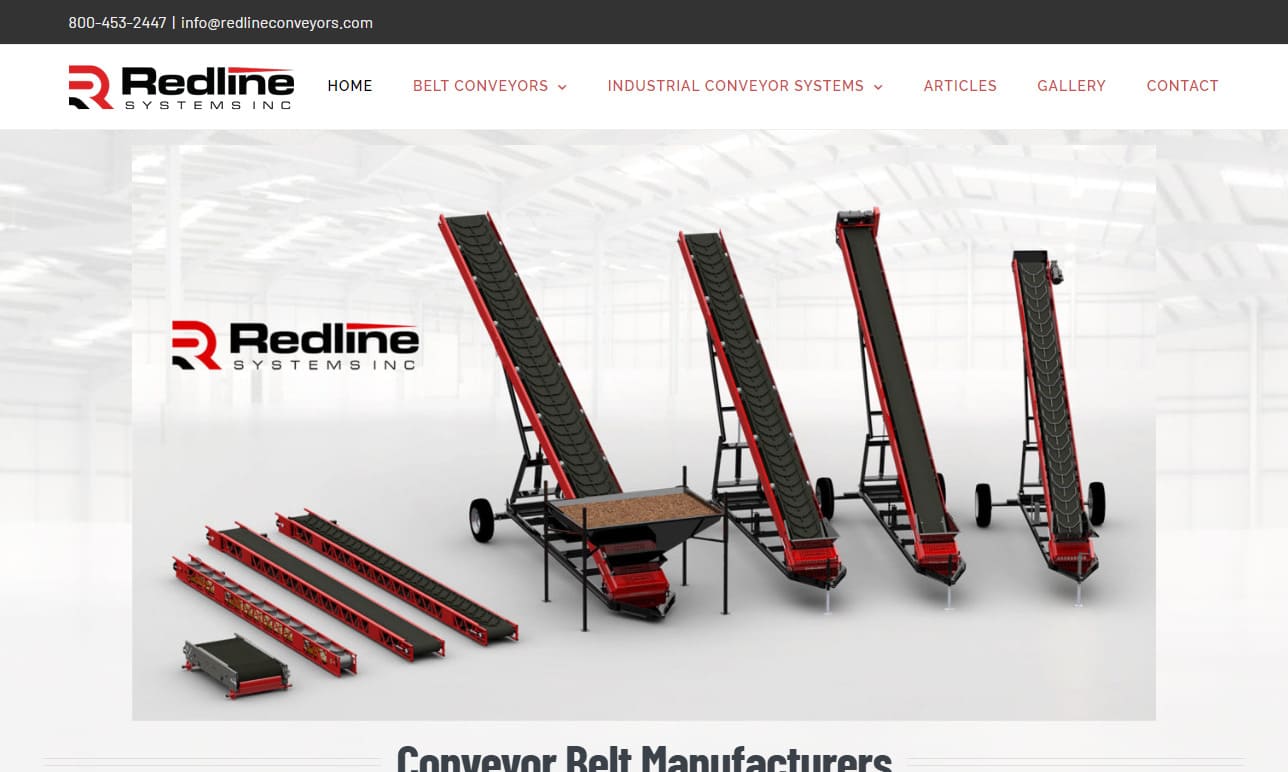

Redline Systems, Inc. is a leading provider of innovative conveyor solutions. They offer various conveyor types, including portable belt conveyors, incline conveyors, horizontal conveyors, stainless conveyors, and more. Experience the difference with Redline Systems, where innovation meets reliability in conveyor technology.

Impact Automation stands as a prominent force in the field of automation, specializing in the design and implementation of advanced conveying systems tailored for diverse manufacturing processes. With a focus on efficiency, precision, and adaptability, we offer a comprehensive product range that includes sorter feed systems, sorter solutions, traditional conveyors, and plastic belt conveyors.

Spiroflow offers a complete range of mechanical conveying solutions in the industry. The staff at Spiroflow can recommend the best method to meet your conveying needs.

Vecoplan leads the charge with cutting-edge technologies that revolutionize waste and recycling. From versatile shredders and granulators to efficient conveying and sorting systems, Vecoplan offers a wide array of solutions for handling wood, paper, plastics, textiles, and more. Our tailored equipment sets new industry standards, meeting the demands of even the most challenging applications.

More Belt Conveyor Manufacturers

How Belt Conveyors Function -

Belt conveyors consist of pulleys (also known as drums) along with a continuous loop of belt material. A belt is stretchy, thick, and durable. Belt conveyors are motorized and powered by an electric motor. The conveyor belt moves when the pulleys on both sides of the belt start working. The motors of these pulleys are given electric current, which makes them move with the same spin and speed, which results in the belt also moving between both of the pulleys.

Rollers are sometimes placed under conveyor belts if the objects are heavy or bulky. The rollers support the conveyor belt to more easily carry the load. Conveyor belts may feature various pulleys, most notably the drive pulley and the idler pulley. The powered pulley is known as the drive pulley, while the unpowered pulley is called the idler pulley.

Belt Conveyor Components -

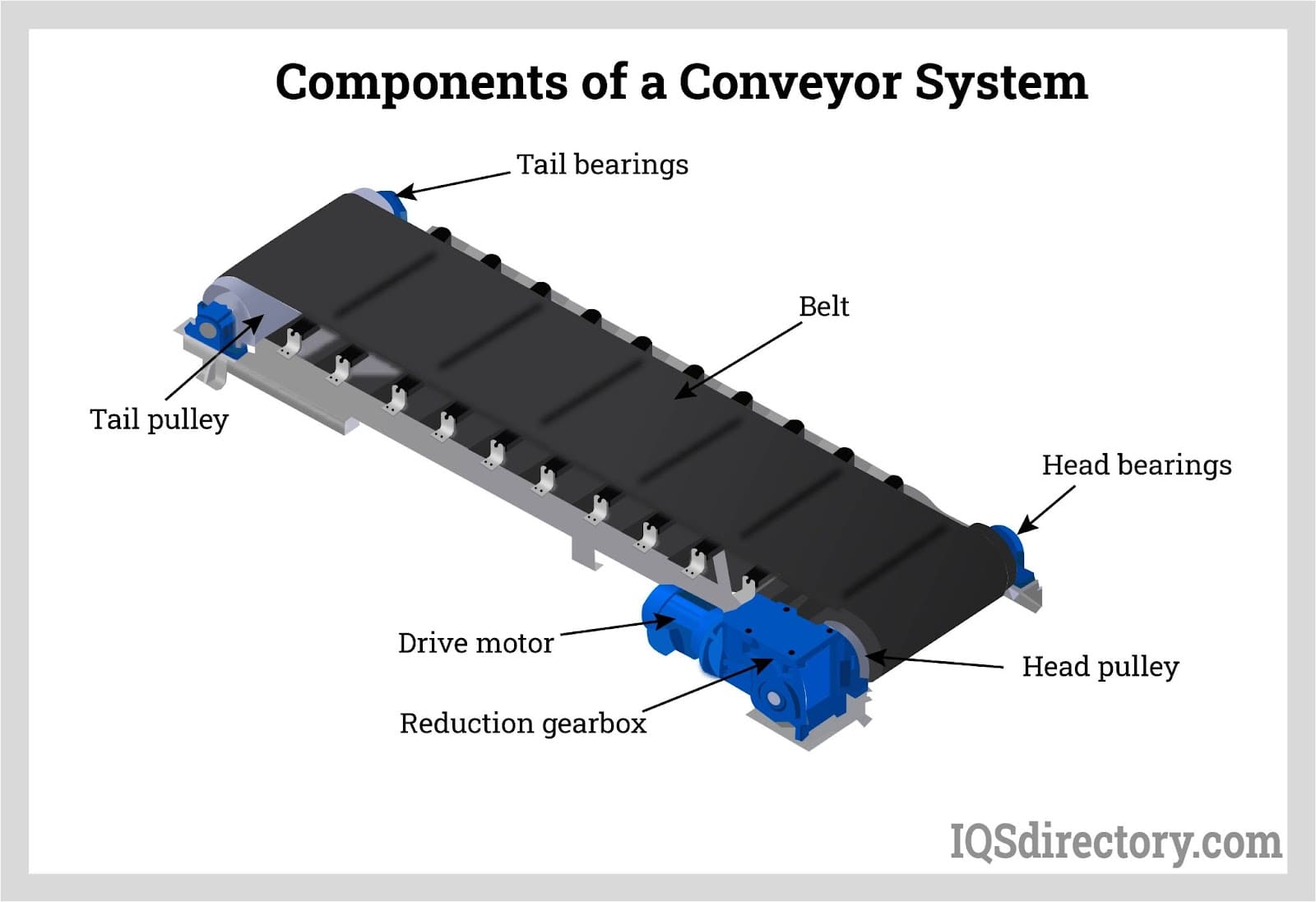

Below are the components of a standard belt conveyor:

Head Pulley -

- Head pulling is the pulley force that drives the conveyor.

- The head pulley is located at the discharging end of the conveyor and has the largest diameter of all pulleys that may be found in a belt conveyor.

- The head pulley is connected to an actuator and an electric motor.

- The head pulley features a “rough jacket,” or legging on its outside which is used to increase traction with the belt.

Tail Pulley -

- The tail pulley is located at the loading end of the conveyor belt.

- The tail pulley functions to direct the belt back to the head pulley.

- A tail pulley sometimes features a series of wing shapes which helps in cleaning the belt by promoting the fall of loose materials before they can accumulate below the belt.

Idler Rollers -

- Idler rollers are placed along a conveyor belt’s length to support the load and the belt.

- Idler rollers prevent sagging, promote belt cleaning, and help align the belt.

- There are many types of idler rollers, including troughing idlers, rubber disk idlers, screw idlers, and trainer idler rollers.

- These various types of rollers are used for different functions for conveyor belts.

Belt -

- The selections of a belt’s design and a belt’s material are the most important choices of a belt conveyor.

- Conveyor carcass is a belt component and is also known as the skeleton of the belt.The main function of conveyor carcass is to provide support, stiffness, and tensile strength to the belt. Conveyor carcass is made up of steel cord or textile ply. Textile ply could be aramid, polyamide, or polyester.

- Belt exteriors are made of flexible rubber or PVC (polyvinyl chloride) thermoplastic.

- Belt material should be corrosion-, heat-, flame-, grease-, and weather- resistant.

- The top side of a conveyor belt could be smooth, corrugated, or cleated depending on its application.

- Various plastic materials such as PVC, PU, and PE have traditionally been used for belts in the food industry. Today, plastic belts are also in demand elsewhere because they are easy to maintain and resistant to acids, chemicals, and contaminations.

Frame -

- The frame of the conveyor belt varies according to the type of load, the height of the machinery it services, and the distance covered by the belt.

- Aluminum extrusions are typically used as belt conveyor frames for applications featuring lightweight operations.

- A calculated and sensibly-designed frame can reduce system failures.

Types of Belt Conveyors -

There are eight types of belt conveyors based on their design and function. These are:

Modular Belt Conveyors -

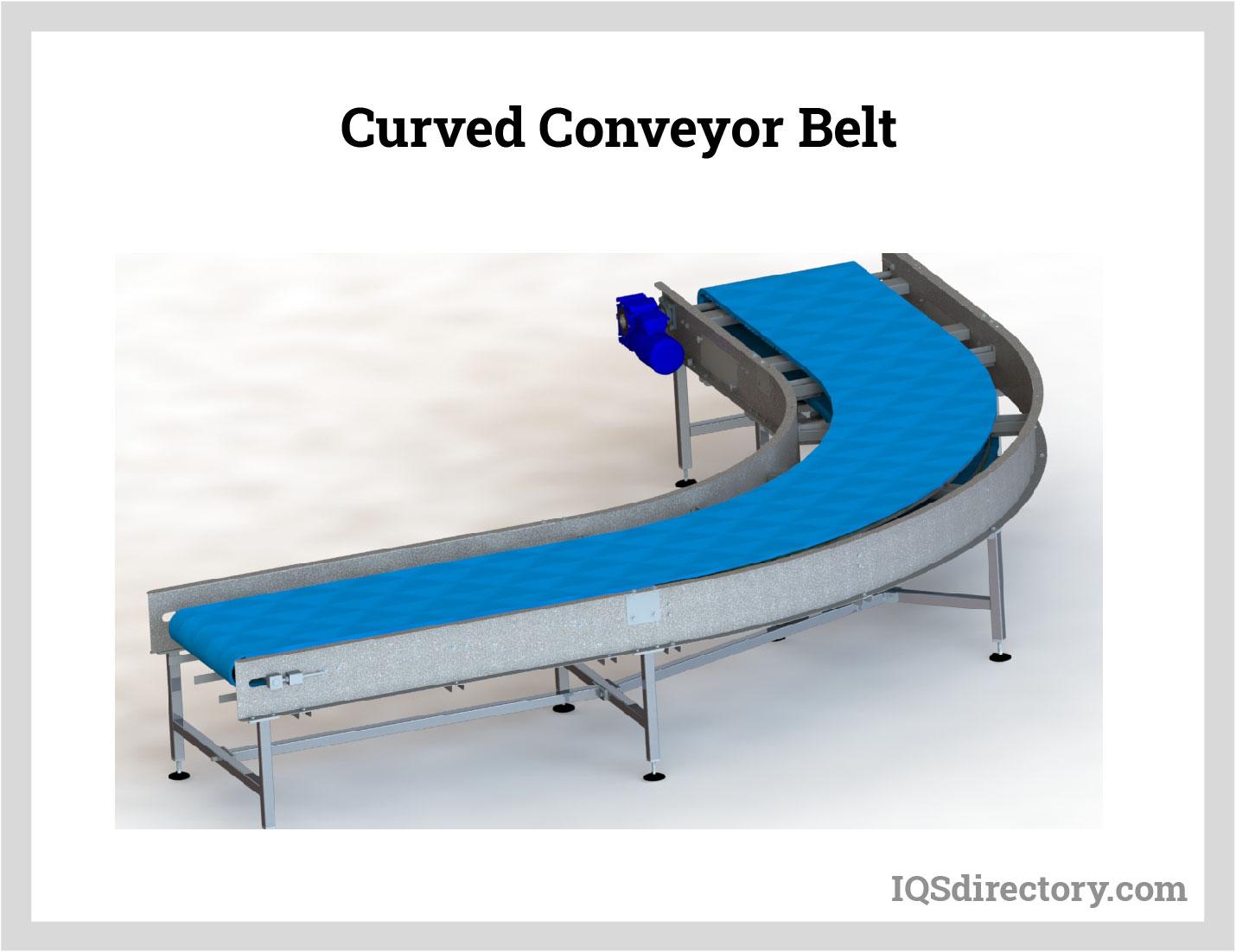

Modular belt conveyors feature chains of interlocking plastic pieces that help in its movement around corners and bends. This belt is useful for conveying various products easily, and damage from sharp objects is very unlikely based on the material used to construct it. Additionally, a modular belt conveyor can be cleaned easily thus making it suitable for food production.

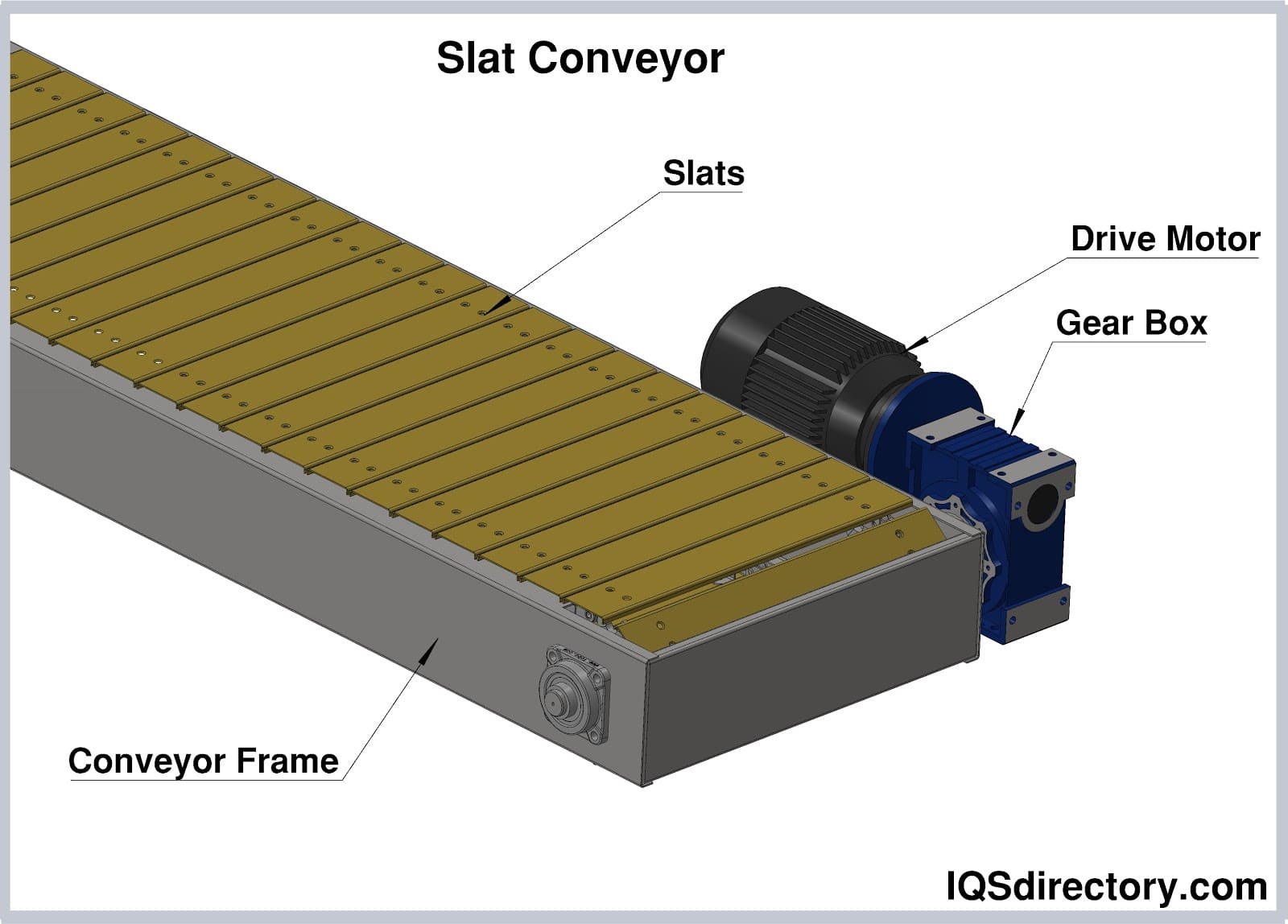

Slat Belt Conveyors -

Slat belt conveyors use slats or plates on roller chains to transport goods. Slat belt conveyors are used to transport heavy objects that are not suitable for standard belts.

Portable Conveyors -

Portable conveyors are made from lightweight materials, are adjustable to accommodate different machinery heights, and generally feature wheels so they can be easily transported. Portable conveyors are used for loading and unloading vehicles, silos and train cars. Portable conveyors are also used in the packaging industry.

Swan Neck Conveyors -

Swan neck conveyors carry objects in an upward direction into a plant’s storage hopper or as part of a facility’s delivery system. These conveyors are sometimes used as a bridge in conveyor systems. Swan neck conveyors feature metal partitions that hold materials in place as they move upwards.

Metering Belt Conveyors -

A metering belt conveyor is used for the separation of items and prevents their accumulation. Metering belt conveyors use sensors to access and separate items by determining an object’s width and space. Metering conveyors should be made with durable material since the separation process routinely starts and stops several times.

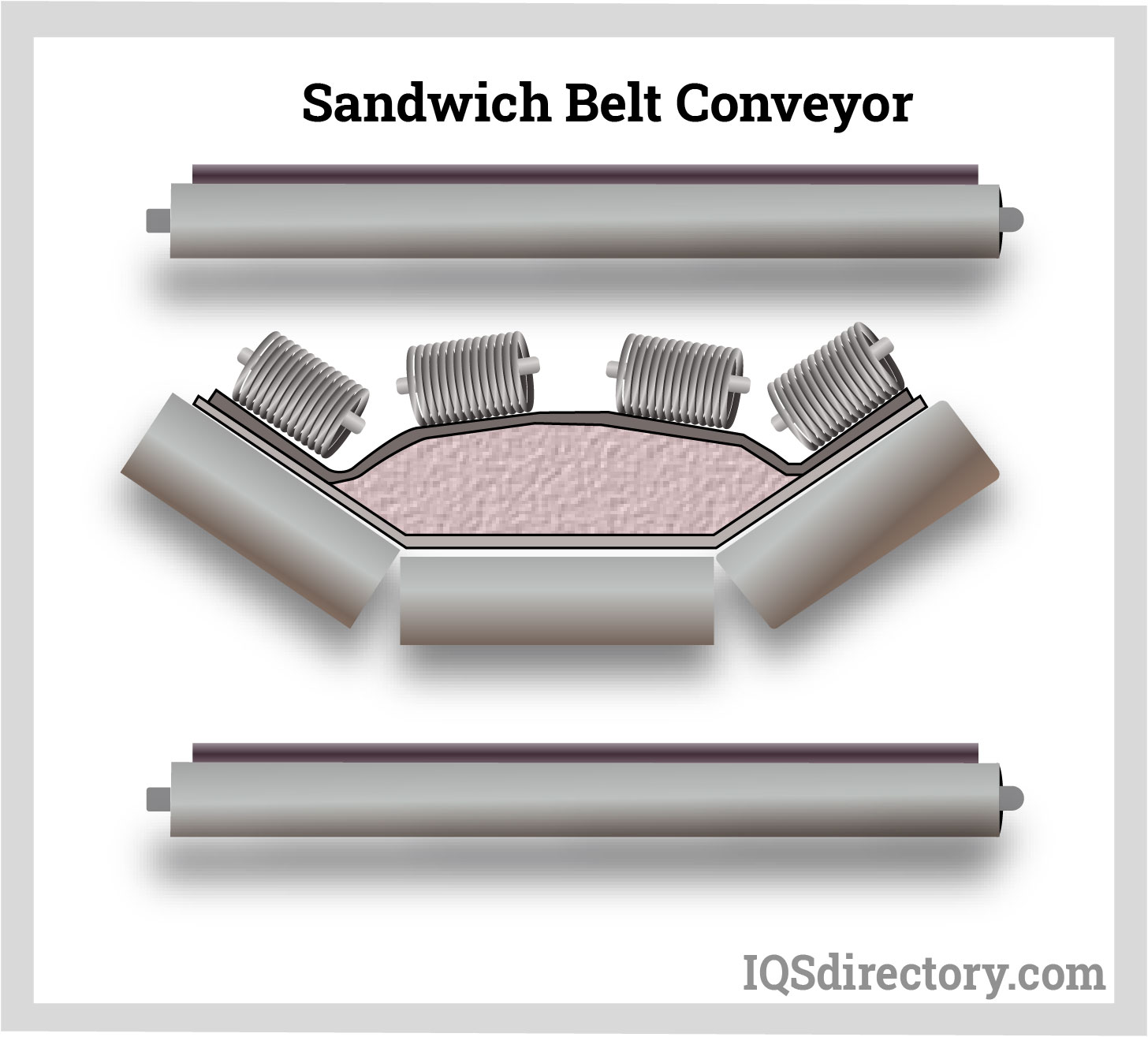

Sandwich Belt Conveyors -

The sandwich belt conveyor is different from others as it uses two conveyors and two belts face to face. The materials that are to be transported are sandwiched firmly between the two belts.

Pipe Belt Conveyors -

Pipe belt conveyors have a belt that rolls together to form pipes or tubes. Idler rollers help maintain their circular shape. These conveyors are best to use where space is limited, and steep inclines are required. In addition, pipe belt conveyors are used with materials where spillage is not likely.

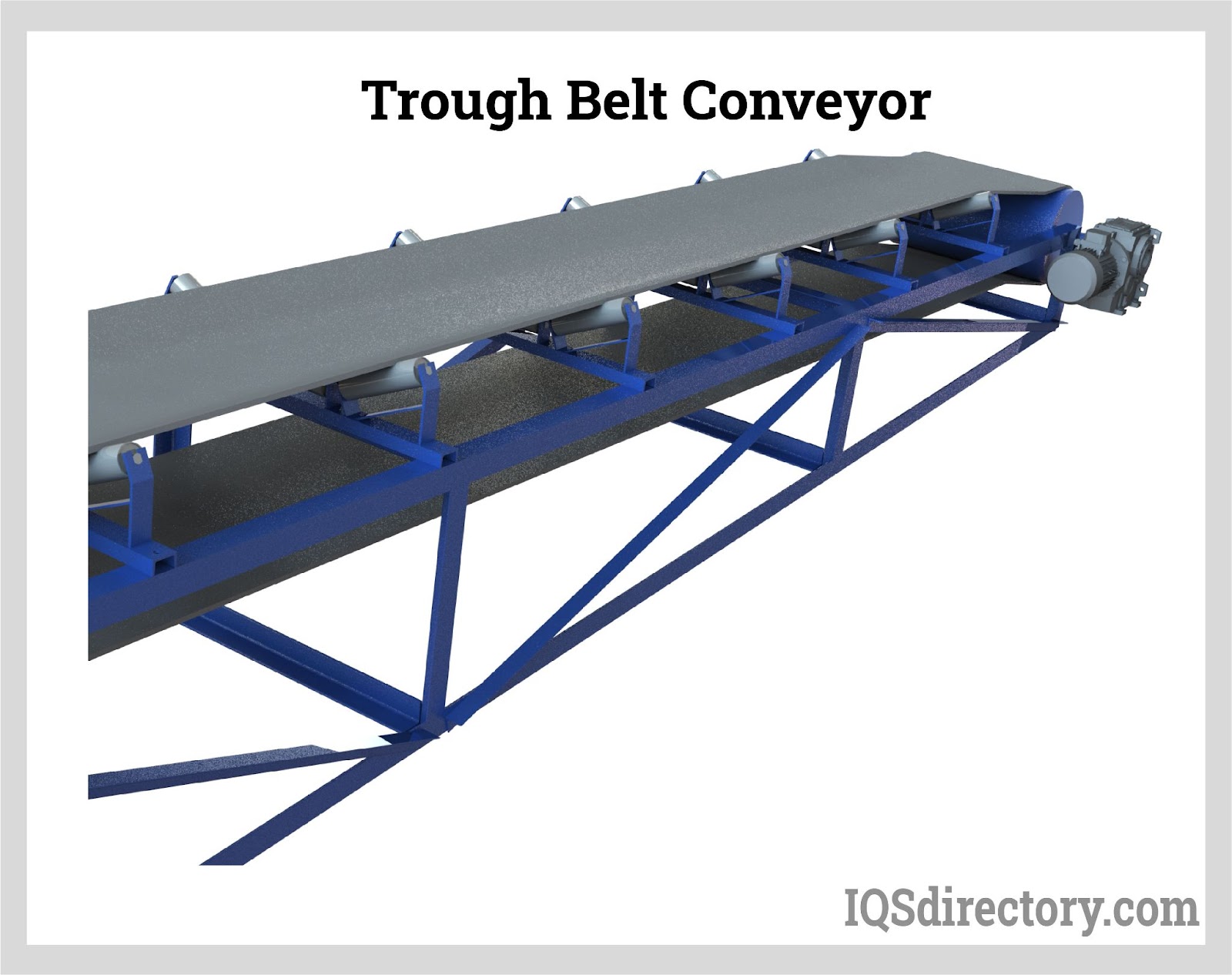

Trough Belt Conveyors -

Trough belt conveyors have a trapezoidal-form and feature edges shaped to contain materials as they move along the belt. Idler rollers are used to maintain the shape and angle of trough shapes within the belt.

Applications of Belt Conveyors -

- Belt conveyors are used in the mining industry when taking ores from the ground, during processing, and for bulk handling applications.

- Belt conveyors are used in automotive assembly lines.

- Belt conveyors are also used in the airline industry to transport baggage to and from aircraft.

- Belt conveyors are used in food handling, power generation, civil, and construction industries.

- Belt conveyors are also used in warehouse packaging.

Choosing the Correct Belt Conveyors Company

To make sure you have the most constructive outcome when purchasing Belt Conveyors from a Belt Conveyors Supplier, it is important to compare at least 4 Manufacturers using our list of Belt Conveyors companies. Each Belt Conveyors Supplier has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each Belt Conveyors business website using our patented website previewer to get an idea of what each business specializes in, and then use our simple RFQ form to contact multiple Belt Conveyors companies with the same form.

Conveyor Belting

Conveyor Belting Conveyor Systems

Conveyor Systems Conveyors

Conveyors Hosereels

Hosereels Industrial Lubricants

Industrial Lubricants Lubricators

Lubricators Screw Conveyors

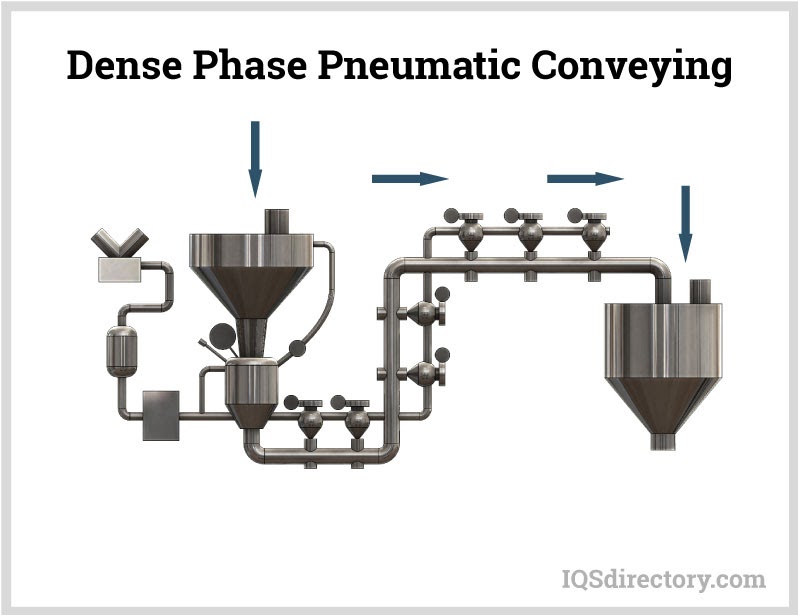

Screw Conveyors Pneumatic Conveyors

Pneumatic Conveyors AGV

AGV Air Pollution Control

Air Pollution Control Assembly Machinery

Assembly Machinery Blowers

Blowers Cranes

Cranes Deburring Machinery

Deburring Machinery Dust Collectors

Dust Collectors Heaters

Heaters Hose Reels

Hose Reels Mezzanines

Mezzanines Modular Buildings

Modular Buildings Storage Racks

Storage Racks Ultrasonic Cleaners

Ultrasonic Cleaners Work Benches

Work Benches