The industry’s most used live conveyor system is a gravity conveyor. They are not only simple to use but also inexpensive, giving warehouse managers and customers a great return on their investment. We’re going to offer you a brief overview of gravity conveyor systems in this article. Read More…

VAC-U-MAX is a premier manufacturer of quality conveyors among other similar products and services. VAC-U-MAX produces its equipment to handle small parts and heavy metal powders.

mk North America, Inc. offers the widest variety of conveyors in the industry. Our vast product line features a variety of aluminum frame and stainless-steel conveyors that are built to last. At mk we believe in offering not only a better product, but also a better solution – which is why we will work with you to ensure your unique application is matched with the best possible conveyor...

At Slate River Systems Inc, we take pride in our expertise as innovators in the field of conveyor systems. With years of collective experience, our team is committed to delivering cutting-edge solutions tailored to meet the diverse needs of our clients. Our conveyor systems are engineered to optimize efficiency and streamline material handling processes across various industries.

Redline Systems, Inc. is a leading provider of innovative conveyor solutions. They offer various conveyor types, including portable belt conveyors, incline conveyors, horizontal conveyors, stainless conveyors, and more. Experience the difference with Redline Systems, where innovation meets reliability in conveyor technology.

Impact Automation stands as a prominent force in the field of automation, specializing in the design and implementation of advanced conveying systems tailored for diverse manufacturing processes. With a focus on efficiency, precision, and adaptability, we offer a comprehensive product range that includes sorter feed systems, sorter solutions, traditional conveyors, and plastic belt conveyors.

Spiroflow offers a complete range of mechanical conveying solutions in the industry. The staff at Spiroflow can recommend the best method to meet your conveying needs.

Vecoplan leads the charge with cutting-edge technologies that revolutionize waste and recycling. From versatile shredders and granulators to efficient conveying and sorting systems, Vecoplan offers a wide array of solutions for handling wood, paper, plastics, textiles, and more. Our tailored equipment sets new industry standards, meeting the demands of even the most challenging applications.

More Gravity Conveyor Manufacturers

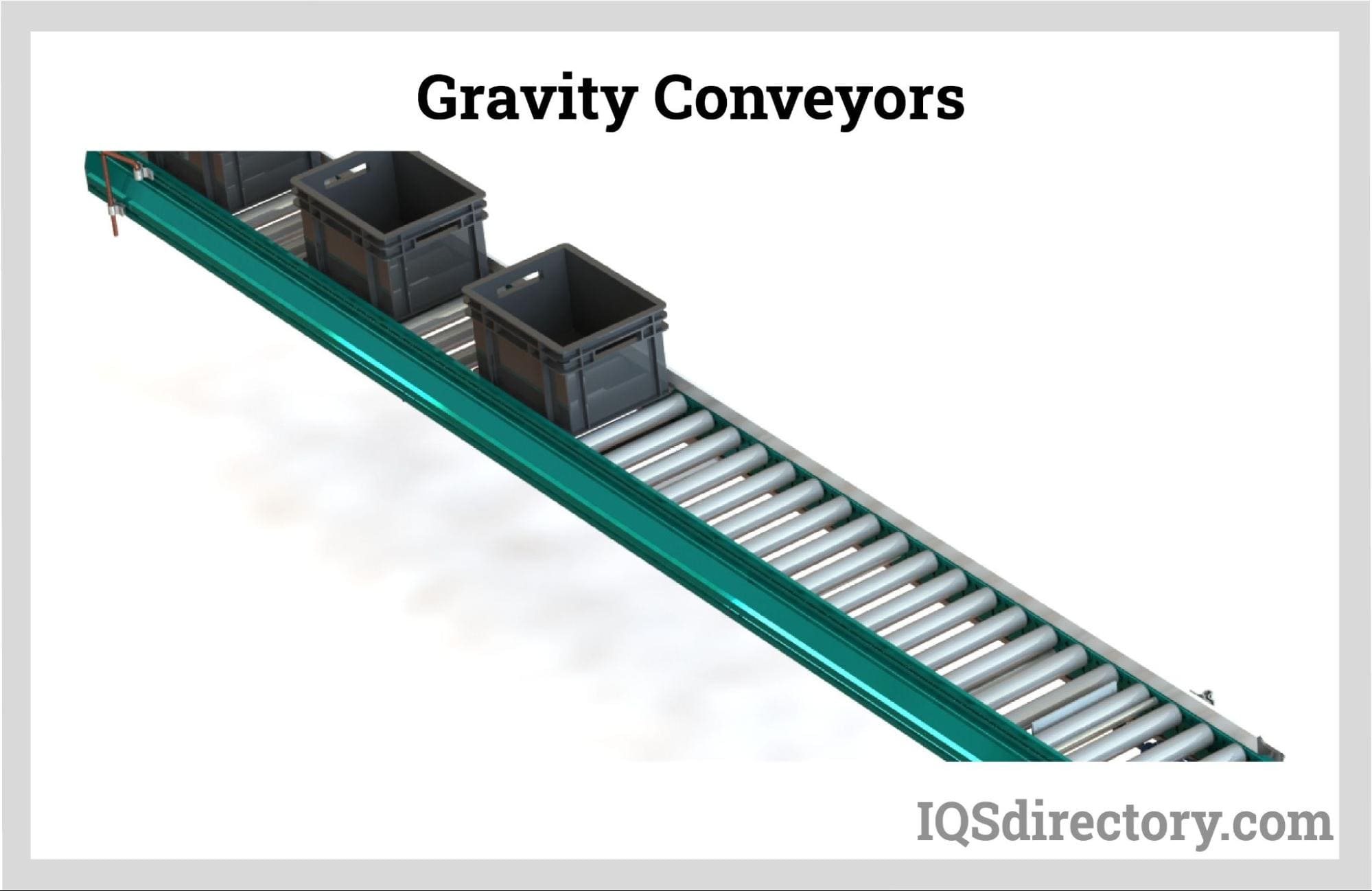

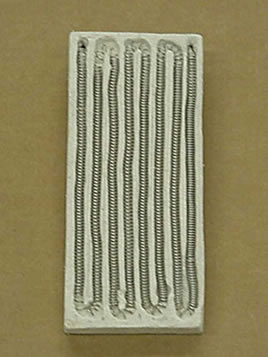

One of the most cost-effective methods for handling materials is using non-powered gravity conveyors. On rollers or skate wheels installed in frames, loads are transported. The name "gravity conveyor" comes from the fact that gravity conveyors are typically inclined in elevation to allow products to flow freely and take advantage of the Earth's gravity. Gravity conveyors are used to move boxes, cartons, and totes with solid, stiff bottoms. The diameters and spacing of roller or skate wheels will vary. A good rule of thumb is that there should always be three rollers or more underneath the box, carton, or tote.

How Does a Gravity Roller Conveyor Work?

A gravity roller conveyor uses the weight of the load to move a product along rollers. Gravity conveyors are one of the most straightforward and cost-effective materials handling systems. They are excellent for distribution centers, manufacturing plants, and warehouses.

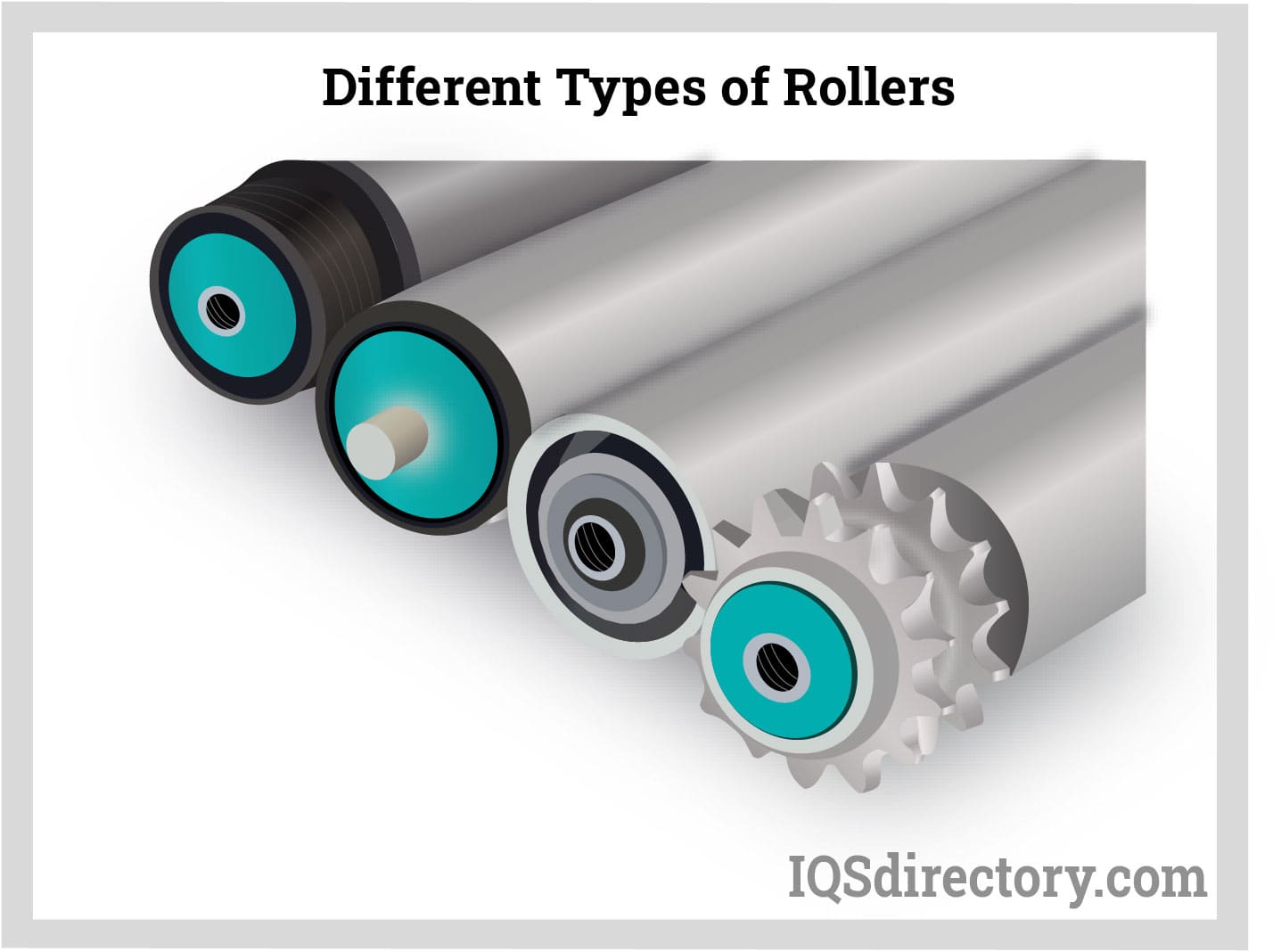

Most of the rollers for these conveyor systems have a diameter of 1.5 inches to 1.9 inches. There are sizes of 2.5 inches and 3.5 inches for heavy-duty applications. System configuration and internet shopping are simple processes. Due to their modest weight, you can use them for short- and long-term uses. There are other options for temporary tripod-style stands or permanent floor supports. For corners, you can use roller curve units.

Installation of Gravity Conveyors

Gravity roller conveyors are typically installed on a decline to convey the product downward to the discharge point, with the infeed at the higher point. If installed properly, a gravity conveyor can operate smoothly, safely, and simply with fewer chances of product damage and higher overall performance.

Installation Considerations

Specify conveyor lines for product weights. The gravity conveyor should be configured for certain product weights to maintain peak performance. For instance, a lighter product could require a steeper descent than a heavier product since the heavier weight can travel toward the discharge end with less gravitational force. It could travel too quickly if you loaded the conveyor with a heavy item.

Conveyor length

Like shorter lines, larger lines can enhance speed because the products pick up speed as they move down the conveyor. The combination of this with rollers that keep spinning after a product has passed over them might result in product acceleration.

Check the product size

Along with the weight, the product's size is crucial. A product base should always be in contact with three rollers or more, so getting the roller spacing right is critical.

Type of rollers

Another aspect to consider when building a gravity roller conveyor is the type of roller itself. Skate wheels enable products to move more swiftly than they would on a standard roller. On the other hand, rollers can handle a wider range of items. Because grease-free bearings roll more swiftly than clean bearings, consideration should also be given to the rollers' bearings.

Speed of the conveyor

You can guarantee that the products stay on the conveyor using the end-stop installation. Additional methods of slowing the items include adding retarding plates, roller brakes, or altering the angle. However, if the product travels too slowly, the conveyor slope can be increased to speed up the product's descent. When the conveyor's slope is steeper, the products move more quickly.

Pretesting the conveyor

The conveyor should undergo testing before being put into use; this will guarantee the best possible product flow and take care of any potential safety issues for the personnel and items on the conveyor line.

Gravity Conveyor Applications

Gravity roller conveyors are a very practical and adaptable mode of transportation with many uses. They are the most prevalent type of conveyor in existence. Gravity conveyors have the following uses:

- Truck loading and unloading

- Equipment loading and unloading for manufacturing

- attaching to scales, carriages, or other industrial equipment

- Within picking regions, conveyance

- regions for assembly or kitting

- The goods transportation

Advantages of Gravity Roller Conveyor Systems

Owning a gravity roller conveyor system has many benefits. The advantages of a gravity roller conveyor system are listed below.

Affordability

Gravity roller conveyors are relatively inexpensive because they don't utilize motors. Additionally, most components are made from steel, aluminum, and plastic—frequently available and universal materials.

Flexibility

These systems are flexible, elastic, and can adapt to customer needs. They are often implemented as temporary conveyors and can be transported without real challenges.

Maintenance

Pallet conveyors are made with gravity roller conveyor designs that are simple to maintain. When one element breaks, it only takes a few seconds to snap a replacement into place because they are primarily manufactured out of inexpensive, accessible materials. It's sometimes as simple as removing the damaged piece and putting in the new one, so you won't have to stop working entirely or look for a specialist.

Disadvantages of Gravity Conveyors

- When products are moved by gravity, they could become harmed.

- unable to regulate conveyor speed

Choosing the Right Gravity Conveyor Company

To make sure you have the most constructive outcome when purchasing Gravity Conveyors from a Gravity Conveyor Supplier, it is important to compare at least 4 or 5 Suppliers using our list of Gravity Conveyor companies. Each Gravity Conveyor Supplier has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each Gravity Conveyor company website using our proprietary website previewer to get an idea of what each business specializes in, and then use our simple RFQ form to contact multiple Gravity Conveyor companies with the same message.

Conveyor Belting

Conveyor Belting Conveyor Systems

Conveyor Systems Conveyors

Conveyors Hosereels

Hosereels Industrial Lubricants

Industrial Lubricants Lubricators

Lubricators Screw Conveyors

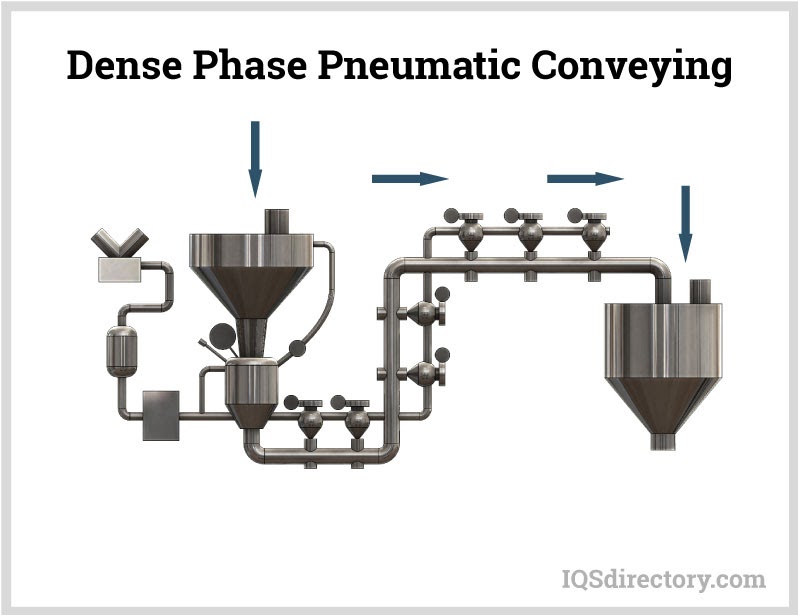

Screw Conveyors Pneumatic Conveyors

Pneumatic Conveyors AGV

AGV Air Pollution Control

Air Pollution Control Assembly Machinery

Assembly Machinery Blowers

Blowers Cranes

Cranes Deburring Machinery

Deburring Machinery Dust Collectors

Dust Collectors Heaters

Heaters Hose Reels

Hose Reels Mezzanines

Mezzanines Modular Buildings

Modular Buildings Storage Racks

Storage Racks Ultrasonic Cleaners

Ultrasonic Cleaners Work Benches

Work Benches